Introduction

Supply chain management – SCM “is the art and science of network management in which multiple business entities and actors are interconnected so that services and products are delivered at the required time and quantity” (Gattorna, 1998). Cox (1995) defined SCM as “the processes from the initial raw materials to the ultimate consumption of the finished product linking across supplier user companies and the functions within and outside a company that enable the value chain to make products and provide services to the customer“. The ability of organizations to be able to react quickly to the supply-demand, with the least delay, often makes the difference between survival and making profits and failure and going bankrupt. With globalization practised, it would be observed that many components and products are manufactured in one corner of the globe and consumed in another. This paper provides an in-depth review of SCM practices, discusses various models and theories and presents some cases of successful and failed SCM implementations. After reading the report, the reader would have a better understanding of the dynamics involved in SCM.

Objectives and Purpose

The objective of the paper is to critically examine different aspects of supply chain management theory and practice, to find emerging trends that shape the SCM and procurement practices; to examine practices and case studies of SCM practices across different regions such as the US, Europe, developing countries, Asia and other areas. The purpose is to create a paper that would bring out the best practices from a wide range of industries covering retail, food, music, manufacturing, apparel and other sectors. Once these findings are obtained, a framework of best practices would be created to help scholars and industries to obtain an overall perspective of SCM.

Rationale for the Research

There is a fine connection between SCM and outsourcing that has become commonly accepted as a term in the English lexicon. Countries such as China, India and other South Asian countries have emerged as the main outsourcing hubs. These countries, with their low-cost labour, low government tariffs and highly skilled workforce, have a unique competitive edge that allows organizations from Europe and the USA to outsource a wide range of products such as automobiles and automobile components, apparel, food items, electronic goods, toys, chemicals and many others. However, while these countries have a competitive advantage in the form of resources, it is still up to the western companies to ensure that they set up a supply chain that allows the raw materials and finished products to move from one destination to other, like a clockwork. However, SCM is not only confined to China or India but to the local vegetable seller, the newspaper vendor, the person who delivers flowers, the music and toy shop down the corner and even the postal mail and courier service that people use every day (Ross, 1998).

There are no prima donnas in the SCM, and it should be remembered that often the weakest and the slowest entity in a network would determine the SCM efficiency and speed. The emphasis is on creating an efficient network in which all the elements are able to scale their activities as per the forecast demand. SCM does not involve the work improvement process at individual organizations as this is a different branch of science, and it is assumed that the entities are ready and willing to make the required improvements and investments for process improvement. SCM is mainly concerned with increasing the reaction speed in a network and how fast and how efficiently goods are transported from one destination to another, consistently and periodically. The work improvement process in an organization is one of the tools and methods that would be used by organizations to improve their sourcing and manufacturing techniques so that they can participate in a successful SCM network. Many organizations such as Tesco, GM, Toyota, Zara and thousands of companies use some form of supply chain management to reach their products. While companies such as Tesco and Toyota have their own SCM systems for procurement, smaller companies use the services of courier companies such as FedEx to send and receive their products. SCM covers almost all aspects of the industry, and it has become a very important process with companies investing millions of dollars to ensure the information and products are received and sent on time (Ross, 1998).

With SCM providing a ‘make or break situation, there is a need for developing an understanding of different aspects of SCM. There has been ample literature and research on specific areas of SCM such as transport, logistics, processes, the importance of software, and a number of case studies on different organizations have also been published. However, these publications provide a fragmented view of SCM practices, and it would be difficult to find a single publication that consolidates and integrates different practices. To a certain extent, this is a gap in the literature, and a reader would have to read multiple sources to understand what SCM practices and theory are. This paper would attempt to bridge the gap and provide the bigger picture and perspective and focus on key aspects of theory and practice.

Emerging trends in SCM

The current economic crisis has fragmented the market, and while the economic recession is a reality, people still have to eat, clothe themselves and go to work if employed. This has produced a different marketing mix where transport companies are faced with reduced load, and this would mean that trucks and ships would not run at reduced capacity and thus increase the overall costs for the transporter, the manufacturer and the vendor. This means that with reduced market share, there is an increased consolidation among transporters and service providers, and it is the age of collaborative practices rather than competition. Practices such as Cross Docking are gaining more importance, and in this process, the use of the warehouse for storage is done away with, and goods are transferred directly from one truck to another. Pooling methods along with transhipment methods are being explored with the goal of reducing inventories to what is actually on the road and stocks in warehouses being kept only for the emergency purpose (O’Marah, 2008).

Demand forecasting has acquired a great urgency, and conventional forecasting models are becoming ineffective because they rely on historical data such as GDP, growth, cost of living index and so on. The recession and the economic slowdown was not predicted well in advance and took just a couple of months to engulf the world. Crude oil was selling at 147 USD per barrel in July, and within a few months, the rate has become less than half, and even this fall in price was not forecasted. With uncertain variables, demand forecast becomes uncertain, and companies cancel orders at the last moment when goods have already been dispatched to a port, and as a result, many of the ports are clogged with a large number of containers and bulk products. This creates a nightmare for transporters and port authorities, and the worst thing is that no one has any solution, and it is a wait and watches attitude (PMI, 2008).

McCrea (9 January 2008) reports that software development and practices in SCM are undergoing a change. The author suggests that new versions of software applications assume both the tasks of planning and execution of strategies and sit on top of the ERP systems that organisations have. Such systems are able to analyse any disruptive patterns more easily and scan the ERP network many times in a day so that applications become more predictive, fast and intelligent. The author also reports the increased use of RFID and GPS systems in the SCM industry, and this trend reflects the need for information that can lead to the decision making process. Frequently, large ERP and SCM systems are integrated with the RFID receivers and are able to track the order, estimate the time required to reach the destination and then appropriately place the work orders. Using such systems reduces the slack in the chain and reduces the inventory holding costs.

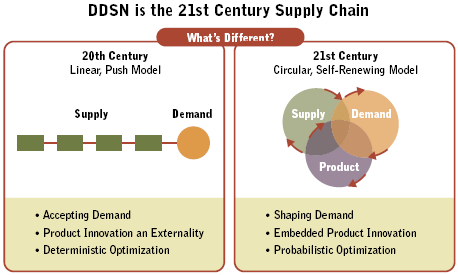

O’Marah (September 2008) points out that the demand-driven supply networks – DDSN of the 20th century have undergone a profound change from the linear push model that was being used. The DDSN model has undergone a change and to a model that has three overlapping responsibility areas, and this is supply management, demand management and product management. Please refer to the following figure that illustrates both models.

The author also speaks of the ‘value chain maturity model with 12 dimensions’, and these are the 12 dimensions that a demand-driven transformation has to cover.

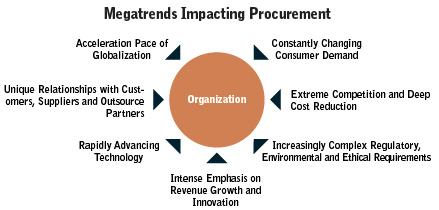

Radjou (2008) has conducted research to understand the implications of SCM practices and how CEOs view SCM practices in the current economic scenario. According to the author, procurement is closely integrated with SCM, and the emphasis is on value addition and cost reduction. Organizations have realised that merely procuring items based on the cost if the vendor is in a remote and far off location has no meaning. This would mean increasing the procurement cost, lost opportunity cost and inventory holding cost. The author has pointed out that there are a number of megatrends that are shaping the SCM industry. These are illustrated in the following figure.

As seen in the above figure, a number of megatrends are impacting procurement, and these would, in turn, serve as the directions for SCM. A major shift is a procurement is closely associated with SCM practices, and large companies need to factor in the delays while calculating the procurement costs.

The thesis would examine the above issues and a number of other issues, both historical and current, to understand how SCM solutions have been actually implemented. There is strong support from both theory and practice in the paper.

Methodology Used

The student first began by studying a number of publications such as trade magazines, news reports, books and peer-reviewed journals to understand the extent of the subject. SCM is a very vast domain with hundreds of niche practices and terms. After a thorough review of the domain, a number of keywords related to SCM were noted down, and some examples were logistics, demand, Tesco, Bull Whip and many others. These keywords were again searched to understand their overall impact on SCM practices, and a long list was prepared to create a list of keywords that would be used in the research. The list was again refined to form a shortlist of final words and headings that were representative of common SCM practices across all industries.

Using these keywords, databases such as ProQuest, Questia, Internet and other sources were searched to find documents that would be considered for the study. The search also yielded a number of organizations that had successfully implemented SCM practices. The documents were perused to obtain a final set of headings, and then a method was used to extract the required ideas from the documents and rewrite the ideas and content to form different chapters. In the course of writing, important notes and points of an article where noted, and these would be later used in the conclusions chapter.

Limitations of the Research

The research has focused on an empirical literature review of a large number of sources and has not attempted to conduct interviews of SCM professionals. However, responses to questions and some survey results have been used to understand the expert’s opinion of the subject.

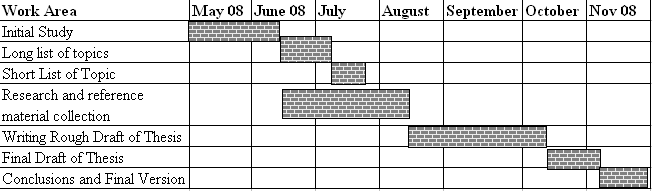

Timeline for research

The research involved different areas and phases and was conducted over a seven-month period, beginning from May 08 and ending on November 08. The timeline of the paper is presented below.

There are certain overlap areas for the Research and Reference material collection, and documents and sources were collected right from the initial study period.

References

- Gattorna John, 1998, Strategic Supply Chain Alignment: Best Practice in Supply Chain Management, Hampshire: England, Gower Publishing Limited, ISBN 0566078252

- O’Marah Kevin. 2008. The Top 25 Supply Chains. Supply Chain Management Review. pp: 16-24.

- McCrea Bridget. 2008. Supply Chain Software and Technology: The Status and the Future. Supply Chain Management Review.

- Radjou Navi. 2008. Trends 2008: SCM Market Outlook. Forrester Research, Inc., Cambridge, MA, USA.

- PMI, 2008. Trade Analysis Container: Containing the bulge. [Online] Port Management International. Journal of Port Management International, 2, pp: 38-40.