Introduction

Oil is one of the major export products of the municipality of Abu Dhabi, in the United Arab Emirates. The UAE on one hand was a province but is now rising from the rubbles of the past through a unified stand from a small population and its leadership who has pushed for modernity, urbanization and rapid growth.

With growth and development comes many problems and challenges; some of these are environmental problem, coping with the many innovations and changes, globalization, technology, and so forth. Problems on preserving the environment and coping with environmental degradation have been one of the major issues in national conferences worldwide. This has not escaped the national leadership and planners of the UAE. They have instituted measures regarding environmental compliance on the part of the various agencies, public and private.

Another major problem that the government has to tackle is the focus on wastewater management and treatment. Oil is its major product and therefore oil waste products in the form of wastewater, which are contaminated with chemicals and substances, have to be dealt with seriously. Major programs have to be formulated to tackle the issue.

At the Abu Dhabi Oil Refinery Complex, managers and leaders under the overall leadership of Yousef Omair bin Yousef, have been working round the clock in tackling environmental problems. The wastewater management program of the complex has been given time and major study in order to address the issue of contamination of chemical and substances that are harmful to the environment.

In this study of the Abu Dhabi Oil Refinery Complex, it was necessary to use a step-by-step process – nearly a scientific approach – in attaining the objectives for this section of the paper. First, we used the Analytical Hierarchy Process (AHP) in comparing the various alternatives, such as technical, economic, environmental and administrative criteria. The AHP is explained in the literature as to how we reached a decision on which technology to use. Most of the information gathered in this study was taken from reliable sources from the internet, databases and books and journals. We provided a discussion, results and analysis, and finally, a conclusion/recommendation.

Oil refineries generate a vast amount of wastewater that needs efficient treatment. Treatment of this sort of wastewater must be chosen from an array of tested treatment processes and from proven criteria. The criteria includes technical, economic, environmental and administrative.

Refineries and industries around the world have the option and the challenge to manage wastewater with the available technology, and the chance to make it reusable for their constituents and the general public. Whether it will be used for human consumption or for other purposes, wastewater has to be treated before disposing it to the sea in order to avoid toxic contamination on the environment. Dangerous toxic chemicals with hydrocarbon components can be found in refinery effluent water. The water should be treated so that contaminants are separated and dissolved.

Petroleum hydrocarbons emit undesirable odor and affect aquatic organisms. Another substance called the naphthenic acid is harmful to plant and animal life. Hydrocarbons cause cancer to humans and animals, and alter ecological balance. Animals that drink contaminated oil get seriously ill in their alimentary tract. Gasoline, which is toxic, can mix with the wastewater streams, and becomes difficult to separate.

The Abu Dhabi Oil Refinery Complex generates several finished products that include liquefied petroleum gases (LPG), naptha reformate, jet fuel, domestic kerosene, gas oil, straight run residue and liquid sulphur. These products produce wastewater that when not treated become harmful substances that will endanger biodiversity. Wastewater from oil refineries is mixed with oil. Toxic chemicals with hydrocarbon components can be found in refinery effluent water. Treatment can eliminate the hydrocarbon components and toxic chemicals.

There are many benefits in proper wastewater management and in reusing wastewater. First is environmental preservation. There will be less water pollution, the rivers and open seas can be free of pollutants. Wastewater can be reused in industries and commercial establishments. In areas where there is less rainfall, wastewater reuse is of paramount importance.

The objective of this paper is to identify criteria of treatment, develop a treatment alternative and select the best one after a discussion of the criteria and treatment processes.

Objectives

- To develop a conceptual framework for the selection of a centralized or de-centralized wastewater treatment facility for the Abu Dhabi Oil Refinery, in the United Arab Emirates;

- To discuss and develop the various treatment alternatives from a list of tested and applied wastewater treatment from existing oil refineries;

- To determine the applicable criteria from a discussion and comparison of the various criteria involved in the treatment process selection.

Selection Criteria

The aim of this section is to select criteria in evaluating the technology to be used for a water treatment of the Abu Dhabi Oil Refinery. This selection can be categorized as multi-criteria decision making where we choose from among the available criteria to arrive at the best process. We have decided to use the analytical hierarchy process in selecting the treatment process.

The different criteria used in selecting centralized or decentralized wastewater treatment facilities are:

- Technical criteria, which looks at the different aspects of performance, reliability, process applicability, resistance to hydraulic shocks, consistency to organic loading shocks, adaptability, compatibility, and electromechanical facilities, among others;

- Economic criteria, which include factors on capital cost, operation and maintenance cost, sludge disposal cost, land requirement and energy requirement;

- Environmental criteria, which may include the degree requirement in treatment, odor generation, visual and safety;

- Administrative criteria, which may include the technical skills requirements of people in charge of the treatment, operation and maintenance, local availability to facilities and stability of wastewater treatment plant operation and use of online monitoring.

Centralized or De-Centralized Systems

The De-Centralized System

The decentralized wastewater system is a localized process, i.e. wastewater management is applied close to where wastewater is generated and the process of treatment is conducted. This is applicable to rural wastewater management systems that may include subsystems, for example collection, treatment and actual reuse. (Halim, Abdel-Halim, & Nazih, n.d.)

The decentralized water system involves collection of waste and wastewater system that will be concentrated through a sewerage system. Some factors affect the size of each subsystem, and these are the administrative, drainage boundaries, not to mention the social and economic conditions of the local communities.

Decentralization has been hailed by some professionals because it has produced benefits like cost reduction, efficient management compared to centralization, reduced danger to the environment and less accidents, and more prospects of water reuse.

“Decentralization requires the choice of efficient and affordable wastewater treatment technologies which can be placed close to the human settlements without causing nuisance to the community” (Halim, Abdel-Halim, & Nazih, n.d.).

The Centralized System

The centralized system has many benefits in absorbing or eliminating hazardous waste. Using administrative criteria for a centralized system is advantageous for the Abu Dhabi Refinery Complex, considering that the complex produces wastewater that is constant to all occupants of the complex.

The Abu Dhabi complex produces 18 million tonnes of oil products annually, and the wastewater produced can become indescribable without the implementation of well-studied and planned wastewater system that exits to the sea or to its sewerage system (Oxford Business group, 2010, p. 96). There are two government-owned facilities being run by the Abu Dhabi Oil Refining Company – the Ruwais and the Umm al-Nar complexes which produce 420,000 bpd and 88,000 bpd, respectively. (Al Abed, 2005, p. 146)

Most of the usable water in Abu Dhabi is treated or is formerly wastewater, treated to become reusable water. The treated wastewater is used for irrigation, in hatcheries and farms, and in commercial and industrial uses. The treatment process also produces sludge that can be used as fertilizer. The quality standard of Abu Dhabi is quite high, as it also adheres to following international standards of wastewater treatment. Biological wastes are converted into purified and sanitized water. (USA International Business Publications, 2007, p. 75)

Environmental laws call for disposal of hydrocarbon flaring, maximum use of land and use of natural resources with least damage, and the proper use and disposal of wastewater into the natural diversity. The potential of wastewater reuse market size for Abu Dhabi can reach $190 million. (USA International Business Publications, 2007, p. 76)

The Methods

The AHP Method

In this study, the Analytical Hierarchy Process (AHP) is used to determine the right criteria for treatment process selection of the Abu Dhabi Oil Refinery. The AHP method is usually applied to processes where there are several criteria that need to be decided. This method which involves assigning numbers to particular steps and activities is quite accurate and guides the decision maker to an exact judgment in the choice of criteria. The AHP also uses assigning numbers to words and then solving a mathematical problem with a formula application. The words are variables which are called fuzzy sets, applied with fuzzy numbers.

“… Fuzzy numbers and fuzzy sets have been introduced to characterize linguistic variables used to represent the imprecise nature of human cognition when we try to translate people’s opinions into spatial data … [and] the preferences in AHP are essentially human judgments based on human perceptions, so fuzzy approaches allow for a more accurate description of the decision-making process” (Karimi, Mehrdadi, Hasemian, Nabi-Bidhendi, & Tavakkoli-Meghaddam, 2011, p. 738).

In AHP, triangular fuzzy numbers (TFN) are assigned to several scales of judgments, and characterized by a series of real numbers, for instance (l, m, u). These parameters are expressed as m provides the maximum grade, while l and u are limits to both ends of the equation.

The AHP is useful in finding the right decision for a problem or problems which can be in the form of a multiple objective linear programming (MOLP). According to Korhonen & Wallenius (2001, p. 37), through AHP “qualitative aspects can be quantified”.

The AHP is also used in the search analysis as applied to MOLP. There are two phases for this method using MOLP problems. The first phase involves providing information – which is to be done by the decision maker (DM) – on the latter’s preference structure with respect to the multiple objectives, and the algorithm provides a solution for the DM to decide using the information he/she has provided. This process is repeated several times until the DM reaches the most applicable decision or solution to the problem. The second phase involves finding the “research direction” in a process introduced by Korhnen and Laakso (1986) wherein the decision maker provides the direction in improving the various values.

Arbel and Oren (1996 cited in Korhonen & Wallenius, 2001) develop a modified version of AHP using an interactive method for the MOLP, wherein the AHP “is used to determine a preference structure over the current solution and its adjacent solutions” (Korhonen & Wallenius, 2001). There are other uses and modified processes introduced by authors and experimenters on the AHP.

The AHP is also used for selecting the best alternative from a comparison of several criteria which are weighted based on another criteria. Mohanty et al. (1993 cited in Datar, 1998, p. 19) stated an example of AHP using several steps, such as: first decide a possible alternative and a comparable base criteria (like performance or cost); compare the alternatives and make a basis for the comparison to form a matrix; make a normal set-up for each matrix; compare again another criteria to form another base matrix; again make a normal set-up for a matrix; and finally, compare the score for each alternative. (Datar, 1998, p. 19)

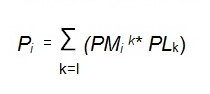

The formula will be:

The one that gets the highest score should be chosen as the best alternative.

Analyzing Qualitative Relationship Using AHP

In finding a solution for a decision problem, it can be solved using a linear model, such as yi, i = l, …, m, which can also be expressed in the decision variables xj, j = l, …, n. This is termed as “linear decision model”, which is expressed in the following equation:

Korhonen and Wallenius (2001) argue that the equation can be expressed in the form of a matrix, such as:

Y = y(x) = Ax

The letter representations are:

- X = n-vector for the decision variables,

- A = mxn coefficient matrix,

- Y = n-vector which includes decision variables xj

In solving this equation, there has to be values that would represent the decision variables xj, j ЄN = {1,2,…,n}.

TOPSIS Method

The Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) is also used for the selection of treatment process. A brief background for the TOPSIS Method states that it was introduced by researchers Hwang and Yoon (1981 cited in Karimi et al., 2011, p. 738). But the TOPSIS method is not applied to this research.

Criteria for Business Process Selection

From the different criteria mentioned above, it can be conceived that it is really difficult to compare them and provide a general criteria in the treatment method selected. There are however positive points that can be applied to the criteria, as can be seen in the description and explanations for each of the four criteria. The general selection is to decide first on a criteria, identify the important ones; develop treatment methods that suit best according to the method used, and evaluate and select the best alternative. This in essence is the framework for which this study is following and has applied all throughout the research.

Economic Criteria

Land Criteria

The sites of the Ruwais Refinery and the Umm al-Nar have been at continuous expansion due to the rapid growth of the oil industry. The sites therefore have to be properly maintained because the complex occupies a big portion of the site. The municipality of Abu Dhabi generates desalinated water for the vast complex and the population; the water produced is roughly 13.2 million gallons. When this is used by the complex, it converts in millions of gallons of wastewater. Aside from the oil complex, there are other industries in the municipality that also generate wastewater. This part assumes that they have their own wastewater treatment which is not a concern of this paper. (Oxford Business Group, 2010, p. 94)

Pricing Structure of a Centralized Wastewater Treatment

Budgetary requirements

Budgetary requirements are needed for the supply of desalinated water, cooling tower and the boiler feedwater. This may not create a big obstacle for the Abu Dhabi Oil Refinery because of its being a government owned entity with a large capital coming in from oil revenues. But considering the large finances involved, there are a number of issues that need to be discussed when talking of expenditures. The required water to process a gallon of crude oil is 2.5 gallons. A typical refinery like the Abu Dhabi Oil Refinery has the capacity to process 8 to 10 million gallons a day of wastewater. A refinery of this type, expenditures for water consumption exceed $100,000 per day. (Kujawski, 2009, p. 22)

Pricing for the Abu Dhabi Oil Refinery Complex requires careful planning because of the big capital and operational costs needed. Different models in the pricing structure can be used. A popular model for pricing is the 3Ps or polluter-pays-principle. This means in the Abu Dhabi Refinery, the waste generator can be identified and the amount of wastewater can be determined by a committee to be appointed for such purpose. Since the oil complex is government-owned, a committee composed of government people may do the investigation and auditing. A model in determining waste fees should be fixed by the committee.

Chemcontrol (1996 cited in Datar, 1998, p. 24) states that a Centralized Hazardous Waste Treatment and Disposal Facility (CHWTDF) should be fixed on the “ability to pay” principle. However, this is not applicable with respect to the Abu Dhabi Oil Refinery, which is financially independent. The operational costs vary for the different occupants of the complex, and the costs have to cover the personnel, maintenance, products and materials, and the finances for the treatment which is quite high.

Detiem (1997 cited in Datar, 1998) provides a model in determining the financial burden for industrial effluent charges. Biochemical oxygen demand (BOD) can be used as a reference point in determining the cost of treatment. Coefficients can be determined by multiplying the cost of BOD with a determined value of a standard BOD. The formula provided for this is as follows:

“Charge = 4.5Q+18.BOD + aNHP1 + bNHP2 + cHP + Mag”

Technical Criteria

The Abu Dhabi complex should use the process of a combination of water separation, chemical processes, and aerobic and anaerobic processes as per the result of the AHP selection method.

Oil in the wastewater of the Abu Dhabi Oil Refinery is classified in three forms:

- Free oil – this is the oil that has floated on top of the water because of buoyancy. Separation of this type of wastewater can be done through separators, combined with biological processes.

- Emulsified oil – this is the oil that that has formed in smaller globules and has stayed in a permanent suspension in the water. A special type of gravity separator is applicable on emulsified oil, much like those made by API.

- Dissolved oil – this is the type of oil that cannot be separated from water merely through gravity separator. Biological treatment is much prepared for this type. (Veenstra, Mohr, & Sanders, 1998, p. 5)

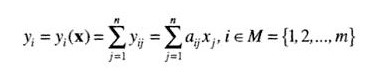

In studying the wastewater of a particular oil refinery, measurements have to be made. An important task is to measure the volume of wastewater coming out from the refinery. The Abu Dhabi Oil Refinery Complex has millions of gallons going out from its plants. These volumes of wastewater have to be measured.

The curve demonstrates the sum of wastewater coming from various sources. The curve shows the volume coming in and entering the wastewater facility. What is significant here is to analyze the curve and the tanks and basins catching the wastewater, along with their variations. Curves can demonstrate the maximum flow of wastewater. Designs of plants and sewers can be determined through hourly flow rates. Statistics can be processed to determine the design of treatment plants. Using fractile diagrams can help in the design process.

More on the design of wastewater treatment plants, it is important that variations of the wastewater are known. These variations mean the flows of the wastewater in the recorded daily, weekly and monthly characteristics of the water along with its pollutants. Nitrogen is one of the substances that should be removed. It is usually present in municipal wastewater but is also present in refinery wastewater. Organics are not absent in wastewater, in fact there are thousands of them roaming around the wastewater. A BOD (biochemical oxygen demand) analysis in wastewater should also be conducted. This concept of BOD analysis in wastewater stems from the fact that microorganisms cause the oxygen demand. The measure of oxygen demand can determine the extreme of pollution in the water. BOD analysis is used in oxidizing organics in the wastewater. However, this is measured with a maximum time of 5 days.

Microorganisms in wastewater also need oxygen, and they do consume oxygen faster than any other. Calculation of BOD can be done based on the demand for 5 days, along with the volume of polluted water. (Henze, 2002, p. 46)

Primary Treatment

Wastewater flows are not constant. This is true with oil refinery complexes which have large plants and require big space to accommodate the millions of gallons of wastewater coming in from the oil refinery. The flows are not steady; they require an expert knowledge of engineering to maintain and manage. Building a treatment plant requires considerable knowledge in the characteristics of the wastewater, its variation and the volume. The Abu Dhabi complex involves millions of gallons of water. The design of the plant alone requires careful study and has to take into consideration the number of occupants, the kind of wastewater that the occupants discharge, and the overall concept of wastewater management and treatment. Several criteria have to be analyzed in order to reach a safe and possibly correct decision.

The treatment for wastewater in an oil refinery is unique in several ways. First, refineries have their own unique ways of wastewater management and treatment. Most of them apply modified and unique forms of treatment and management, depending on external and internal environment of the organization. At the Abu Dhabi complex for example, the features and programs have their own style as formulated by the managers and leadership of the complex. The management of the complex takes into consideration several factors to include cost effectiveness, environmental preservation, and other factors.

The primary treatment – or the first step in the technical aspect of wastewater treatment – is separation. Oil or solid materials have to be separated first from the water before the waste water can be treated. This is the reason why the Abu Dhabi Refinery uses (or has to use) a combination of technical aspects of wastewater treatment.

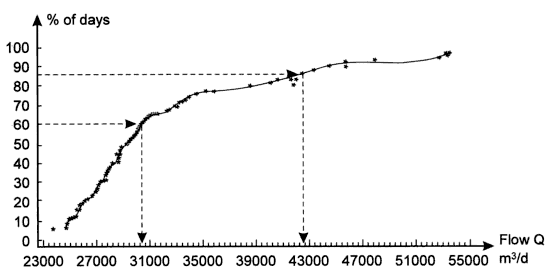

As explained in the literature, the first stage consists of the separation process, and common in many oil refineries is the application of an API separator, or sometimes with a corrugated plate interceptor. In this initial stage, oil, solids and water have to be separated from each other in order for the next stage to commence. The next stage may be a biological process. (Speight, 2005, p. 279)

Wastewater has to move through a slow process in the separation stage. Oil has to float through the surface in order for the separation process to occur. Other solid materials will settle at the bottom of the water where another collecting ‘agent’ known as “sludge-collecting hopper” will do the job. The second stage will consist of biological or chemical treatment.

There are other physical methods like the use of settling ponds or large basins. The Abu Dhabi complex uses large containers and basins in the physical treatment. In this stage, treatment may consist of dissolved air flotation (DAF) or induced air flotation (IAF), where air bubbles carrying the oil are skimmed off or removed from the top of the water.

Refineries use chemicals like ferric hydroxide or aluminum hydroxide in the coagulation process, or in the skimming off of the impurities present in the wastewater. Hazardous substances are then removed from the wastewater, and the next will be the exit of the water to a stream or body of water. Water reuse can be one of the benefits in the process. In some countries, like the United States, water exit goes through a publicly owned treatment works (POTW). The water may undergo another treatment process before going through the next stage of exit in a natural body of water. In the United States, this is done with a permit known as National Pollution Discharge Elimination System (NPDES) permit. (Speight, 2005, p. 279)

Oil Separation

Oil separation gets its attention from the decision makers. To separate oil from wastewater means to remove the impurities in the water. There are many ways of separating oil from the wastewater, but one of the most common is through the API separators.

The usual parameter is to make the oil float as in the air flotation methods. Other methods include the use of gravity to make the oil float at the top of the water. This is the natural way. Oil droplets are made to float on top of the water. The plant or refinery has to build big tanks or basins for the gravitational separation to occur.

At the surface of the wastewater is sheen which develops when there is enough oil in the water. This should be removed, or treatment should be done to remove the sheen. Usually, sheen develops when there is enough hydrocarbon concentration of more than 15 mg/L. Oil separation will reduce the hydrocarbon concentration to less than 15 mg/L. Some states in the United States require an effluent concentration of 10 mg/L while other countries like Canada require even down to 5 mg/L. API Separators are critically observed by some authors or commentators for not having met the required 15 mg/L concentration. They are only designed to collect large oil droplets the size of 150 micron and up. (Veenstra et al., 1998, p. 6)

The different forms of oil in wastewater determine the kind of treatment to be used in cleaning the wastewater. The different forms of oil are: the free oil, which rises up to the surface of the water through buoyancy in the form of oil globules; the emulsified oil, which forms in a part of the water into small microns; and the dissolved oil which has to be treated biologically. These forms of oil are present at the Abu Dhabi Oil Refinery.

The API separators are common in many other refineries and plants. The separation uses the Stokes’s law principle to determine the properties of fluid. This equation, formulated by George Gabriel Stokes, states that: F=6(pi)RnVc; where R is the radius of a particular sphere, to be multiplied with n, which is the viscosity, and the Vc or the velocity of the fluid.

API separators were designed to collect oil droplets of up to 150 microns. The Clean Water Act of the United States stipulates that hydrocarbon concentration should not be more than 15 mg/L. API separators are closed to attaining this. API can be combined with other treatment processes. Gravity separation is also one of the effective means of oil separation from wastewater. Gravity separation can achieve an effluent of 10 mg/L or less, and can be more effective if another system is added in instances when oil content is required to be below 10-20 mg/L. It is recommended in the literature that coalescing plates or air flotation systems can be combined to gravity separation system to make it more effective.

API separators are popular but firms have second thoughts on its application due to various criticisms. However, API separators are not at all bad if some modifications are made. A coalescing filter added to the API separators can enhance the performance. In small applications, it is advisable to use a cartridge type prefilter to enhance the efficiency of API separators and remove free oils. Removal of oil from the wastewater down from its previous 15 mg/l is a significant improvement.

The American Petroleum Institute realized the shortcomings of its separator designs. In a survey in 1985, they found that API designs were not generating the required effluent qualities, meaning there was the presence of an excess of 200 mg/L of hydrocarbons in the effluents. This further means that API separators do not perform the way they were design to. But as previously discussed, a combination of several methods can produce positive results.

Other kinds of separators include the so-called coalescing plate separators which reduce the distance that droplets can go before they are being seized, and reduces the size of the separator. One technique in this method is to tilt the separator to minimize too much space. Commercial types of this kind are available and some companies sell patented coalescing plate separators. Another one is the multiple angle separators, which is an improvement of the coalescing plate separator. The action involves plugging the solid particles in the wastewater with oil.

Other methods of separation include the separation by gravity using flotation of the oil droplets on top of the water. This is also called natural gravitational separation. Reverse osmosis is quite expensive. It is an action of reversing natural osmosis, wherein the water passes through a thin skin surface, applied with amount of pressure. It produces 25% concentrate of pure water.

Anaerobic/Aerobic

In the study of the literature, we have discussed the processes of biological treatment in wastewater; these are called secondary processes or biological treatment in various forms. As stated, microorganisms are used in decomposing the wastewater to remove the contaminants and other substances. The Abu Dhabi Oil Refinery uses several processes which combine separation and anaerobic treatment.

Anaerobic treatment in the oil refinery includes:

- Anaerobic biological degradation which involves biological degradation of organic sludge in wastewater;

- Anaerobic Baffled Reactors.

Refinery wastewater such as that produced by the Abu Dhabi Oil Refinery has been traditionally treated in a number of ways such as oil separation, and primary and secondary treatment. Biological treatment is commendable and is common in many refineries particularly in the Middle East region. This treatment includes aeration and the introduction of other treatment technologies.

In an oil refinery, there are a number of contributors to the flow of wastewater which includes process water, cooling tower blowdown which contributes to about 60-80% of the entire flow, and clean water. (Peeters and Theodoulou, 2005, p. 2)

Because of the presence of high concentration of ammonia, metals and other chemicals, refinery wastewater has become toxic and needs to be treated through biological processes to restore its usability. Organic compounds present in oil and in wastewater can be treated with anaerobic process. In the anaerobic system, the organic matter can be converted into biogas.

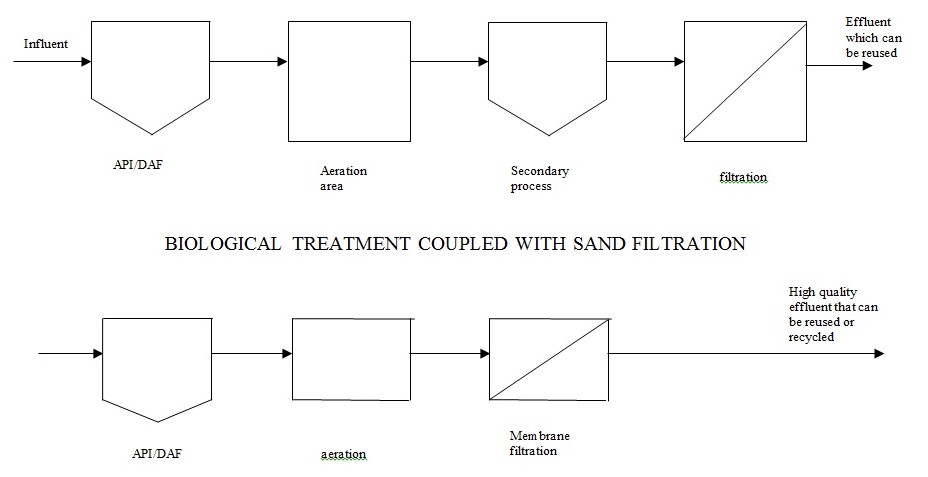

The process that is commendable for the Abu Dhabi Oil Refinery is a combination of biological processes, separation and membrane filtration, which when integrated would result into a configuration known as a Membrane Bioreactor System (MBR).(Peeters and Theodoulou, 2005)

There are limitations in this process because of the presence of some by-products of oil wastewater. By-products of wastewater from refineries include asphalt and residua. Usual test methods have to be modified in the presence of residua and asphalt because these compositions do not dissolve with ordinary solvents.

Membrane Filtration

This uses a membrane that serves as a barrier to the entry of matter in a water flow. There are some classifications of the membrane which is determined through the size of the pore and the weight of the molecules that pass through the membrane. A membrane can be a permeable or semi-permeable material that prohibits the entry or motion of smaller species. It also has the control of “relative rates of transport of various species through itself and thus, as with all separation gives one product depleted in certain components and a second product depleted in other components” (Ghag & Mahanwar, 2010, p. 2010).

As discussed in the earlier sections of this paper, we have the microfiltration which employs microfilters with large pores, and separates molecules with the weight of 100,000, which is as big as 0.05 to 20 microns. Also in the filtration category are the ultrafiltration and the nanofiltration. Reverse osmosis is quality oriented in that it separates molecules smaller than 0.0015 microns.

There are also microfilters which can hold smaller particles such as those smaller than pores. They can retain the bacteria but cannot separate other materials which are colloidal. A common microfilter is a certain organic polymer with even pore dimension. Nanofilters are used to remove dissolved molecules even down to the smallest molecular mass of treated water. The nanofilters have extremely small pore diameter that exert operational pressure which is greater than other filters, like the ultrafilter.

Flotation Processes

Flotation processes are also called Dissolved Air Flotation (DAF) or Induced Air Flotation (IAF), which have the capability of removing suspended solids and oils from wastewater of an oil refinery. Flotation is also useful for other solids and oil coming from a petrochemical wastewater. (Lavallee and Nadreau, 1997; Al-Muzaini et al., 1994 cited in Rigas, Panteleos & Laoudis, 2000, p. 245)

Flotation uses the same coagulants and flocculants used in gravity method. There are some advantages than the usual gravity method. For example, foam flotation is effective in removing color, inorganics and soluble organics (Malley and Edzwald, 1991 cited in Rigas et al., 2000, p. 246). Flocculation uses chemical with aluminium or ferric salts and can only be done when there are suspended solid particles still present after the action of separation. The flocculants are mixed with and circulated in the water. The advantage to this kind of action is that the sulphides can be removed with the solid particles and low levels of hydrocarbon can be attained. However the action can also produce large quantities of hydrocarbon with sludge.

Air flotation is recommended by many experimenters and researchers because of the relative economy of space it provides and the short time needed to impound the wastewater. DAF is another effective wastewater treatment, which uses coagulants and flocculants that are effective in gravity separation. This is advisable to refineries which want to implement quality wastewater treatment management at less cost. Flotation methods are more effective in oil-water separation in municipal or oil refinery wastewater. More firms now that rely on this type of oil separation. But DAF is much preferred than IAF because of the size of the bubbles produced in DAF. DAF combined with the principles of gravity separation can be a good oil separation technique.

There have been successful studies involving IAF. Rigas et al.’s (2000) study utilized the IAF bench-scale flotation method which was constructed for the purpose. They used an IAF separator which was a semi-cell consisting of three cells; the technique was to obtain a high efficiency which was at least 90%. The laboratory separator was set at 1.751.1, and they applied a one-stage treatment instead of the usual 3-stage treatment method and applying detention time of 50 minutes. The overflow rate was 0.15 m3 m-2 h-1. Added to this experiment was a porous glass air disperser, forcing air to penetrate the wastewater. This process was used in the Standards Methods (1992).

Rigas et al.’s study used aluminum sulfate and NALCO 71403. The conclusion for this experiment proved that a one-stage flotation integrated with a central composite design is effective in determining the effects of flotation. The chemical doses were also determined with this experiment. Air flotation should have a combination of other methods in order to have an effective treatment. Air flotation system can be combined with a composite design to be effective in determining the effects of flotation and the chemical to be used in the treatment process.

As stated, the membrane technology which is applicable to the Abu Dhabi Oil Refinery will integrate both a biological reactor and an ultrafiltration membrane technique. Example of a process flow comparison between a Membrane Bioreactor to a traditional biological treatment process is shown in Figure 1.

Biological removal reactors are effective in removing oil and grease from water. The process involves several stages until contaminants and other substances are removed from the water. One stage involves nitrification to complete the action of removing ammonia.

A bioreactor also involves flotation method and clarifiers that separate the biological sludge from the effluent water. They also apply effluent biofilters which separate solids and other compounds. Another application is a vertical U-tube aerobic digester, and another group of biofilters to treat the odor from the air. The method used in the bioreactor involves injecting air into the lower and upper portions of the reactor to allow air to get in and circulate. The organic matter becomes stable, after which a line along the shaft that has a depth of 76 meters moves the solids to the flocculation portions, and the dissolved air flotation is executed.

The bioreactor’s primary objective is to remove organic compounds from the wastewater. This is a vertical shaft bioreactor which has a casing of 1.8 meters in diameter, with a depth of 105 m, and which is sealed at the bottom. Biological oxidation in the main reactor is executed through injection of the air which drives the circulation process. Effluent wastewater is injected from the deep down below and is allowed to rotate at a circuit.

Optimum extraction speed is executed by the bioreactor through the pressure produced from the head tank, the vent stacks, and the biofilters. This extraction velocity is controlled to prevent unexpected dissolution. The head tank and the flocculation chamber will have a simultaneous extraction when a substance, which is actually a mixed liquor containing bubbles, mixes the wastewater.

The advantage of the bioreactor installation in a petrochemical refinery is that wastewater or effluent is easily biodegraded, wherein the process produces some compounds which are termed ‘refractory’. The compounds can be easily treated in the biofilters which are attached to the bioreactor. The process of doing this mechanism of the filters involves: entrapment of the solid waste particles, absorption of other materials, and oxidation of the other organics.

Anaerobic is more beneficial to other alternatives. Anaerobic results into conservation of energy because it does not use a method which may resort into destruction of organic matter; instead, energy is preserved by converting organic waste into biogas. Anaerobic also produces minimal excess sludge.

Of particular attention here is the one used in Petrobas, Brazil, which is the most successful wastewater biological technology (Kujawski, 2009, p. 23). This treatment is used for the separation of oil and grease from wastewater, with the use of a sequential batch reactor (SBR). It is connected online, which means it can be remotely operated and controlled. Two sequential batch reactors were alternately used. The process used several stages of biological removal reactors. The first stage is the process of removing oil and grease and other hydrocarbons that come from petroleum substances. It involved a sequential batch reactor. In the second stage, the submerged fixed film, a biological reactor, is used to spread the sulphur oxidizing bacteria to produce the effluent quality of the water. This process is used to dissolve or eliminate the organic sulphur compounds. The third stage involved a complete ammonia removal through nitrification. The first and second stages have performed nitrification but the process was not complete, therefore in this last stage, the action of ammonia removal is completed.

Over the past years, there has been development in the study of anaerobic reactors. This involved the creation of two anaerobic reactors – the anaerobic baffled reactor (ABR) and the other one is the anaerobic migrating blanket reactor, also known as the AMBR. The baffled reactor consists of three or four stages using baffles to manipulate the flow of wastewater downward in each stage in the reactor. The direction is also pushed in an upflow mode. The solids are captured in each stage, and there has been modifications concerning the baffle reactor stages. The ABR has some advantages, as follows:

- The reactor is simple and no mechanical mixing is involved;

- There is a longer SRT with respect to the time of the hydraulic system;

- Kinetics is improved

- The operation continues effectively despite the shock created. (Stensel, Stensel, & Strand, 2004).

Environmental Criteria

Waste minimization is one way of answering the continuous environmental degradation of the rivers, streams, the seas and other bodies of water by oil refineries. The government should adapt a waste minimization scheme in addition to wastewater treatment. This is one way of addressing environmental problems that have become a worldwide concern. Abu Dhabi sits on the tenth of the worlds’ oil reserve, with a production of more than 400,000 bpd of oil at Ruwais, and the one at Umm al-Nar with a capacity of 88,000 bpd (Oxford Business Group, 2010, p. 94).

An oil refinery produces hazardous substances and pollutants that are harmful to the environment. Waste means any material that has to be discarded because it is “no longer part of the normal commercial cycle or chain of utility” (Institute of Civil Engineers, 1995, p. 8). With this definition, waste becomes a broad term. In the planning stage of waste minimization, waste materials are easily defined and properly handled.

The topic on environmental protection also reflects on the health of individuals in the community, to include the workers and employees of the oil refinery. Protecting the environment, having a waste minimization plan, and managing wastewater treatment to ensure better implementation of waste disposal, are tantamount to preserving the health of the people.

Eliminating waste requires a lot of resources, not to mention political will, unity between the contractor and the client, volunteerism from the community, and a whole lot of efforts from the workers in the site, as stringent measures have to be instituted to minimize the negative implications of refineries’ wastes to the environment.

Datar (1998) states that in-plant waste minimization includes changes in the processes inside the plant, substitution of existing raw materials and other products, and effective in-plant management and house-keeping.

Yousef Omair bin Yousef, head of the Abu Dhabi National Oil Company (ADNOC), says that the government company has instituted measures for the reduction of CO2 emissions and another mechanism known as gas flaring. They have future plans for adoption of “zero flaring” for all of ADNOC’s major projects. (Oxford Business Group, 2010, p. 94)

Other environmental programs undertaken by the government include the establishment of agencies to protect the environment and promote environmental programs and activities. Agencies like the Environmental Agency for Abu Dhabi (EAD) had been formed to implement the UAE Federal Environmental Law 24 (1999). The government also instituted programs for environmental compliance in the rural areas, created agencies for environment preservation, and also pushed for treatment and disposal of medical waste. (USA International Business Publications, 2007, p. 74)

Recent Studies

The Middle East countries have been experiencing unprecedented growth these past decades due to the rising oil prices, caused by some nationalist sentiments in several parts of the region. The economic growth has some serious environmental repercussions, particularly marine, air and surface pollution.

Abu Dhabi is ahead from the rest in the region when it comes to economic growth, but it has to face the serious environmental degradation, if it does not act now. Oil is its primary source of economic miracle, thus it has to address the environmental impact caused by the oil refinery complex. Not too long ago, the Abu Dhabi Emirate published a government manifesto titled “Masdar Initiative” with an accompanying document known as “Plan Abu Dhabi 2030” which promotes an “orderly urban construction” with a well-established environmental program and landscaping, including development of new energy resources and other sustainable development program for the Abu Dhabi Emirate. (Japan External Trade Organization (JETRO) Xenesys Inc. Mitsubishi Corporation, 2009)

ADNOC has been pushing for environmental preservation programs through energy saving policies. It is on the lead as a government arm for environmental compliance under the Kyoto Protocol. ADNOC is one of the founding members of this world body. Abu Dhabi has worked for CO2 emission reduction in its many oil complexes and facilities throughout the country, and is on the lead among other members of the United Arab Emirates when it comes to environmental compliance.

One of the many programs of environmental preservation of the Emirate, not to mention effective wastewater treatment, minimization and reduction, is the “waste heat recovery type”, an energy saving tool that itself generates energy. This technology makes use of the waste heat from the atmosphere, to be transformed into energy and fresh water. A recovery boiler takes hold of the waste heat as soon as it reaches 200°C, but it is not effective in recovering heat at a temperature of 50° to 150°C. With this technology, there is less emission of carbon dioxide into the atmosphere, particularly at the oil refinery complex.

There are many factors to be considered before the selection of the effective wastewater treatment. The plant has to be well designed so that there will be no health hazards. Bad odor produced by the treated effluent water should be minimized or removed; chemicals and other toxic substances must be properly handled and not pose as health hazards to animals and humans.

Administrative Criteria

The administration of the Abu Dhabi Oil Refinery Complex is under the ADNOC but under the policy directives of the Supreme Petroleum Council headed by the Crown Prince Sheikh Khalifa bin zayed Al Nahyan. A directorate under the ADNOC is responsible for the planning and administration of the oil complex, including wastewater management. This administrative body oversees the operation of the wastewater treatment facilities, including the technical skills requirements of the workers and employees, maintenance and plant operation. The head of the eight directorates involving administration and control of ADNOC is Yousef Omair bin Yousef. (Butt, 2001, p. 236)

Recently, the ADNOC, along with its subsidiaries commissioned a private company, Fichtner, to conduct feasibility studies on its existing plants, regarding the effectiveness of the various facilities, including environmental compliance, and refurbishment/rehabilitation, or retirement, of these plants. The complex has a Core Area and its rehabilitation and modernization are one of the main concerns of the government, particularly the state-owned ADNOC. Fichtner’s main goals include several aspects, such as the technical and financial aspects, environmental competence, and economic performance. (Fichtner, n.d.)

On-line monitoring for wastewater treatment is one of the applications provided for the Abu Dhabi complex. The wastewater passes through a big sewer system, passing through a pump which is being reinforced by a high velocity analyzer. From the analyzer, big particles of sludge are extracted, and also applied with a “spill detector” that alarms once oil and carbon leaks. (ODS Sampling and Analytical Systems, n.d.)

Gravitational separation is executed in big tanks. A method known as enhanced gravitational separation is done using centrifugal force. Other refineries use distillation. There are also those who use reverse osmosis and absorption, but these methods are sometimes expensive and too costly on the part of the company. But as mentioned earlier, financing is a problem of the Abu Dhabi Oil Refinery.

The administrative criteria for wastewater treatment have to consider the following:

- Applicability – This focuses on the experience and information available for the plant, such as the Abu Dhabi Oil complex. If the technology has been applied and effective for the complex, then it has to go on. If new changes and innovations are already in place, there should be a study as to its effectiveness.

- Performance – This can be measured through the results or the quality of the effluent water including it variability. Alternatives are measured with respect to the quality of the effluents, the percentage BOD, and the suspended solids.

- Reliability – the reliability of the existing treatment technology has to be measured or analyzed according to experience.

- “Resistance to hydraulic shocks” – another variable to be evaluated.

Conclusion/Recommendations

Clean water is a prime necessity in the existence of living things. In countries where there is law rainfall and less water underground, water reuse and recycling are one of the primary options to commensurate for the low supply of water from nature. In the United Arab Emirates, wastewater treatment is a government priority. The Emirates spend millions of dollars for the processing and treatment of wastewater coming out from oil refineries and complexes. Managers and leaders of the government tasked to manage wastewater treatment, and the preservation of water and the environment, are being kept abreast of the new technology and effective methods in wastewater management and other applications. They have been considered experts and consultants in this field of new technology study because of the vast knowledge and expertise they have acquired in the course of implementing wastewater treatment at the Abu Dhabi complex.

The modern methods of wastewater treatment applied with new technology, Information Technology and the Internet, is already too far from the old one, which was considered “end-of-pipe” method, where simple ways of leading the wastewater flows had resulted into further contamination of the wastewater, instead of treating it to become usable again. We have now technologies which are termed “effluent treatment processes”, centralized and de-centralized treatment, and so on. The main thrust of the new concept in wastewater is to save water through recycling or treating the contaminated water to become fresh again.

The Abu Dhabi Oil Refinery Complex uses a combination of oil separation and biological treatment to have an effective wastewater treatment. The effective means for technical criteria involved first, separation, followed by biological reactors to effect the treatment process. The APH method used is effective in the selection of technology. It was used to determine the right criteria for the treatment process selection of the Abu Dhabi Oil Refinery. The AHP method is usually applied to processes where there are several criteria that need to be decided. The process is accurate because it guides the decision maker to a near-correct decision where before cognition of human judgment had to work on unreliable factors.

The different criteria mentioned in the literature require a whole lot of study before making any judgment or decision. It requires time and effort and many other resources in putting together the vast information and data, in analyzing and putting some researches and studies.

The AHP method was created to aid the researcher and the people involved in the job of refining oil and its corresponding wastewater created in the course of business.

References

Al-Abed, I., Vine, P., & Hellyer, P. (2005). United Arab Emirates yearbook. Abu Dhabi, UAE: Trident Press.

Butt, G. (2001). Oil and gas in the UAE. In I. Al-abed & P. Hellyer, Eds., United Arab Emirates: a new perspective. Bookcraft, UK: Trident Press Ltd.

Datar, R. (1998). Planning a central hazardous waste treatment and disposal facility: analysis of technology alternatives. A thesis submitted in partial fulfillment of the requirements for the degree of Master of Engineering, Asian Institute of Technology, School of Environment, Resources and Development, Bangkok,Thailand, December 1998.

Fichtner (n.d.). Examples of energy economy studies. 2011. Web.

Ghag, K. S. & Mahanwar, P. A. (2010). Membrane synthesis for separation (Part I). Chemical Business. Retrieved from: City University London database.

Halim, H. S. A., Abdel-Halim, W., & Nazih, M. (n.d.). Selection and Evaluation of Appropriate Sanitation Systems in Rural Egypt. Case Study in Sohag Governorate, Upper Egypt.

Henze, M. (2002). Wastewater, volumes and composition. In: U. Förstner, R. J. Murphy, & W. H. Rulkens, Eds., Wastewater treatment: biological and chemical processes. Berlin; Heidelbert; New York: Springer.

Institute of Civil Engineers (1995). Managing and minimizing construction waste: a practical guide. London: Thomas Telford Publications.

Japan External Trade Organization (JETRO) Xenesys Inc. Mitsubishi Corporation (2009). The study on environmentally friendly energy saving system for the power generation and desalination project on downstream petroleum sector in United Arab Emirates. Commissioned by the Ministry of Economy Trade and Industry. Web.

Karimi, A. R., Mehrdadi, N., Hashemian, S. J., Nabi-Bidhendi, Gh. R., & Tavakkoli-Moghaddam, R. (2011). Using of the fuzzy TOPSIS and fuzzy AHP methods for wastewater treatment process selection. International Journal of Academic Research, Vol. 3. No. 1. 2011, Part III.

Korhonen, P. & Wallenius, J. (2001). On using the AHP in multiple objective linear programming. In: D. Schmoldt, J. Kangas, G. Mendoza & M. Pesonen, Eds., The analytic hierarchy process in natural resource and environmental decision making. Dordrecht, The Netherlands; MA, U.S.A.: Kluwer Academic Publishers.

Kujawski, D. (2009). Trends in oil refinery water reclamation. Pollution Engineering, July 2000. Retrieved from: City University London.

ODS Sampling and Analytical Systems (n.d.). ODS specialist in samples & analytical systems. Web.

Oxford Business Group (2010). The report: Abu Dhabi 2010. UK: Oxford Business Group.

Peeters, J. G. & Theodoulou, S. L. (2005). Membrane technology treating oily wastewater for reuse. Corrosion 2005, NACE International.

Rigas, F., Panteleos, P., & Laoudis, C. (2000). Central composite design in a refinery’s wastewater treatment by air flotation. Globas Nes: the Inte. J. Vol 2, No 3, pp 245-253, 2000.

Speight, J. G. (2005). Environmental analysis and technology for the refining industry. Hoboken, New Jersey; Canada: John Wiley & Sons, Inc.

Stensel, D. H. & Strand, S. E. (2004). Evaluation of feasibility of methods to minimize biomass production from biotreatment. Alexandria, VA; London, United Kingdom: IWA Publishing.

USA International Business Publications (2007). Doing business and investing in United Arab Emirates Guide. United States of America: International Business Publications, USA.

Van Lier, J. B. & Lettinga Associates Foundation (n.d.). Anaerobic industrial wastewater treatment; perspectives for closing water and resource cycles.

Veenstra, J., Mohr, K., & Sanders, D. A. (1998). Refinery wastewater management using multiple-angle oil water separators. A paper presented at the International Petroleum Environment Conference, Albuquerque, Mexico.