Executive summary

This report encompasses the strategic evaluation of a leading company of the world automotive market – Toyota. The initial analysiwill commence with a short historical background of Toyota followed by an analysis of the company in terms of relevant managerial theories including SWOT, PEST, and competitive model analysis. CSR policy will be helpful in understanding the parties involved in overall strategic development and implementation of the company. Discussion over intended managerial style will show how different sorts of managerial visions and practices are influencing the entire functioning and performance of Toyota with a major emphasise on lean, TQM and JIT themes. The leadership practice will focus on the nature of leadership agenda practiced in Toyota along with an evaluation of corporate working environment in terms of motivational and human resource surroundings. Manufacturing is one of the most of the integral parts of this firm since its overall performance mostly depends on the quality and functionality of this unit. The company has also modified such section by introducing upbeat production procedures. Supply web is another essential unit, which requires a careful and well management. Technological overview will clarify various means of technological contributions of the company with its R&D division. Then, the financial strategy will overview many issues related to development and versioning of monetary structure of the company along with some practical financial scenario. The strategic overview of marketing will show several marketing practices and tools adopted by Toyota among with more significant in PLC, STP, Ansoff’s model, BCG matrix, pull-communication, etc. The internal control process will overview some established managerial controlling measures within the firs. Subsequently, a balanced scorecard model will assist to judge the overall effectiveness followed by some suggesting phases to convert operational obstacles into long- term advantages.

Background of the company

Toyota is the simple and popular version of Toyota Motor Corporation, which is mainly a multinational company. It is one of the largest automotive manufacturer occupying headquarter in Japan at Toyota City, Tokyo and Aichi. In 1937, the company had established by Kiichiro Toyota inherently from his father’s organization for the production of automobiles, which was named as Toyota Industries. Before doing so, this group produced different types of engines in 1934 while in 1936, the 1st passenger vehicle- the Toyota AA had manufactured. At present, the company is the legal owner of various globally branded cars including Lexus, Scion, Isuzu, Yamaha, and Mitsubishi with about 522 subsidiaries. The historical review of the company is characterised with many difficulties, which are observed in 1973, 1980, 1982, 1989, 1990, 1997, 1999, 2001, and 2002. This year, the company had been able for making an entrance into a Formula 1 functionality group through the development of joint ownership with Citroen and Peugeot (French automobile company) for the manufacturing of motor vehicles in France. Toyota occupies 397.05 billion yen of capital with 320808 employees for operating its worldwide operation. Additionally, it also achieved the honor of being 8th in the world’s topmost companies in 2005 by Forbes magazine, while it had been the largest automaker in terms of sales during the 1st 4 months of 2008. The year 2007 was also notable for the company’s history for the exposition of complete size truck named as Tundra, manufactured in Texas and Indiana. This truck was been recognized as “Truck of the year” and Toyota branded Camry as “Car of the year” by “”Motor Trend” for the same year. Now, the company is the most giant automotive producer internationally in terms of net assets, revenue, sales, and incomes. Many other industry specialists also believe that the company has been a market leader from early 1960 and continuously been more industrious than other competitors are. Correspondingly, its corporate growth and sustainability are also increasing gradually for its capability of producing qualified cars along with standard production system. However, the company is motivated by the exposition and implementation of some organizational philosophies. Those are related with law, natural environment, employees, customers and others. Maintenance of all such philosophical view requires obligation of national and international laws, honor for local public, cultural and traditional background, and contribution for national living for keeping a safe and clean environment, concern for developmental activities and ensuring participative and co- operative climate for the working people. The global operation of the company is also reflecting long-run strategic thinking as a major managerial decision, use of constructive process for solving complexities and difficulties, organizational development by improving internal HR and use of continuous improvement planning for the solution of baseline problems through a corporate learning process. This automotive company also incorporates different production philosophy, strengthening its international technological backbone, sophistication of corporate culture, reformation of logistics and supply chain management, assortment of diversification of offered items as introduction of “e- com” vehicles, pickup trucks, TRD and Motorsport etc. Although the company has experienced a reduced profit in early 1990 as well as in recent period for the disastrous effect of global economic recession, it is now trying to recover this condition by adopting several logical approaches regarding cutting expenditures and more dispersion of its international manufacturing and selling market. Toyota is also committed to serve a hybrid option on its overall product composition of trucks, cars, and SUVs within this year with an expectation of earning cumulative sales of such criteria of motor cars.

However, the accomplishment of licensing agreement to Ford in 2006 resulted in reduced expenditure of own hybrids to people by increasing overall dominance of the company within this sector. The company is outstanding for initiating environment friendly transportation elucidation for individual markets instigating non-economic purpose to the society. In this regard, it has experimented with Brazilian and European market along with further innovative proceedings for enhancing vehicle capacity by lowering weight and size. Moreover, the company expanded in relation with huge market presence for which it had established a number of manufacturing units in many zones of the world apart from its homeland including China, Australia, UAE, Russia, Philippines, Thailand, U.S.A, Taiwan, India, Portugal, Turkey, Colombia, Canada, Poland, Mexico, Malaysia, Vietnam, Argentina and Venezuela etc. According to the prior knowledge, Toyota has to face some uncertain events during its entire lifetime journey. For example, because of ongoing financial crisis, the company had to sacrifice its continuous record of global profits margin in 2008 by first yearly loss within 70 years. For this purpose, it had declared the shutting down of all of its facilities in Japan for 11 years in order to lower production and inventory of unsold motor cars in 2009.

Company analysis

For making an analytical view of the company, it would be helpful to discuss several evidences regarding the monetary and non- monetary performances of the company within the light different theories, such as- SWOT and PEST analysis, Porter’s 5 forces model of competition and the like (Toyota Industries 2009).

SWOT analysis

SWOT stands for Strength, weakness, opportunity and threat of a company while some of such variables of Toyota are:

Strengths: Some stronger criteria of Toyota are:

- Investment initiation of Toyota in U.S.A and China has shown a greater increase in profit rather than the entire industrial picture. Such as, net income increased from 0.8% to 1.17 trillion Yen since total sales were 7.3% more at 18.55 trillion yen. According to industrial groups, such income had earned because of offering perfect combination of motorcars that the market desires. Therefore, the company is competent in terms of emphasise on proper STP (Segmenting, Targeting and Positioning) strategy in each individual operating nation.

- During the year 2003, the company had recorded to become second giant car manufacturing company with 6.78 million units in the world replacing Ford. Toyota had also been competent in relation with General Motors with 8.59 million units at the same period. Still now, the company is keeping up such significant position in its local and international market because of a number of factors regarding product diversification, standard quality orientation, use of stronger marketing and communication vehicles, introduction of lean production system, progressive management with teamwork, introduction of sustainable development etc.

- Toyota’s target marketing strategy offers a greater portion of superiority within its overall functional background. From that point of view, it can be idealised that it manufactures a wide extent of differentiated motor cars for both individual customers and commercial corporations ranging from mini Yaris to giant trucks. Additionally, the company undertakes various marketing strategies for locating and satisfying their target customer needs. It’s brand name also powerful enough to make positive image in customer’s mind. It also tries to maximize revenues by the application of efficient manufacturing technique in terms of TQM (Total Quality Management).

- International presence is one of the major factor for developing a global orientation and position while the company operates its international operation in about 170 nations.

- Implementation of market penetration approach in basic markets regarding U.S.A, EMEA, and China for the vision of gaining majority of the market share;

- Past record of achieving a higher sales growth and profit recorder as sales turnover of £131511 million in 1997 along with a growth integer of 29.3% during the same financial year;

- TQM (2009) argued that evolvement of various differentiated and modern approaches other than TQM involving JIT (Just in Time) for gaining first mover advantage in vehicle production industry.

Weaknesses: Several major drawbacks of the company are:

- Since, the global motor vehicle market is saturated characterised by over supply, each carmaker needs to be ensured about the most demanding model of their produced units (Christopher 2005). Toyota’s basic selling market is Japan and U.S.A, which can be greatly featured by fluctuated economical and political situations. For this circumstance, the company is shifting its selling vision towards rising automotive car market of China, which offers lower profit margin than general projection.

- The major requirement of huge investment, fixed costs, excessive cost for training and development of workers and capitalization are eligible to put greater pressure on any car manufacturer regarding Toyota. Those variables also generate the problems of over capacity through downturn and lower sales or under capacity for upturn and thus generate a dilemma of proper balance.

- Brand perception by some industry participants as Japanese overseas importer (Pascale & Athos 1981);

- Global criticism in 2005 because of wider- scale re- call factor of quality.

Opportunities: Some potential emerging criteria of the company are:

- Toyota has gained emotional support of community for the production of environmentally friendly cars with Prius. Adoption of sophisticated technologies has reduced the consumption of oil is responsible for improving sales while selling of such technology to Ford has also enlightened the company’s enthusiasm and funding in hybrid R and D sector.

- Introduction of new Aygo by targeting “urban youth” segment would be resulted in gaining a larger market share. Since this pattern of vehicle is an exclusive convertible regarding models and lifetime, such niche marketing would be effective by better branding and earnings.

- Innovative motto of developing new types of cars according to socio- cultural demand involving hybrid fuels, electronic cars, and Eco- vas are assisting in manufacturing, utilization and dumping.

- Adoption of international strategy, especially in highly populated regions enlisting India, China, and Russia would generate long- run return.

Threats: Some threatening conditions are:

- The tendency of not detailing the recalling cost had negatively influenced selling of cars in Japan, Europe, and Australia.

- Huge national and international competition, especially in South Korea, China, and Eastern Europe;

- Increased fluctuation of raw inputs price regarding steel, rubber, and fuel;

- Financial vulnerability for recent global economic depression and slowing down of basic economic economies of U.S.A, Pacific, and Europe for the generation of corporate financial crisis.

- Alteration of demographic scenario in terms of unpredictable demand for mega family cars;

- Rapid use of many other transportation substitutes and increased oil price for lower general demand level.

PEST analysis

It stands for Political, Economic, Socio- cultural and Technological factors of the company (Hitt, Ireland, & Hoskisson, 2001). Such as:

- Political factors: FDI policy of overseas government, specifically, China creates a major impact on Toyota’s Chinese operation as a joint venture. Apart from that, various government incentives, like- tax exemption, tax credit of automobile pool lanes for plug- in hybrid proprietors, hostile government attitude in Nigeria and Venezuela, instable environment in Middle East regarding Iraq war, Israel- Palestine clash, and Iranian tension etc. are posing major influence on Toyota’s operation.

- Economic factors: Enhancement of oil and gasoline price and tax, fluctuated international demand for manufacturing car, extended demand, and rising competitive pressure through domestic production intensity and recessionary effects are notable in this case.

- Socio- cultural factors: Corporate concern for natural environment, inconvenient trust of $42 million in box office in terms of huge celebrity endorsement for reducing greenhouse effect have been effective in creating positive image of hybrid vehicles. Meanwhile, the company is also working in a promotional program for the global application of ITS with different public agencies, academic centers, private area and other social institutions for gaining a better co- operation and co- ordination with that sources. Besides that, adoption of various environmental awareness activities naming as “arrival of a revitalized recycling- based society”, “Global Warming Countermeasures” and “Biodiversity Conservation” etc. have been simultaneously taken by the company.

- Technological environment: Innovative approach of Toyota in terms of developing powertarin technology for adopting “sustainable mobility”, next- generation hybrid power technology for gaining efficiency, automobile safety technology in terms of both active and passive perception including VSC, ABS (Anti- Lock Brake System) and Brake Assist and ITS etc. Lowering the weight of hybrid cars by 50% and price of such technology from $4000 to $1900 per unit are also significant achievement by this automaker.

Competitor analysis

In this regard, we will use Porter’s 5 forces model of competition to understand the competitive environment of Toyota (Toyota Motor Co. (2009). The projected 5 factors are:

- Threats from new entrants: Toyota is continuously facing this pressure from many regions under its global operation because of a number of external forces. For example, especially, in the emerging and densely populated market of China and India, the company is experiencing huge competitive stress from newer domestic carmakers because of governmental leverages and incentives regarding nationalism (Porter 2004).

- Bargaining power of suppliers: Car manufacturing suppliers are generally raw materials companies delivering steel, aluminum, fuel, rubber etc. In different regions, power of these suppliers varies, for example, in China, bargaining power of domestic vendors vary regarding quality and price. Lithium Lon Battery Manufacturers are major suppliers group of the company for delivering technical components for producing hybrid cars.

- Bargaining power of buyers: In this market, buyers are relatively less powerful since in most of the cases, they keep major concentration on quality; also, it varies from country- to- country. However, the present recessionary pressure has changed this circumstance by increasing such power of buyers. Individual consumers, corporations, rental car organizations, and government fleet combine the buyers group.

- Threats of substitute products: Besides different motor vehicles from other direct competitors, Toyota has to face stiff competition from some other alternative transportations like- public transports, buses, railways, trams, bicycles etc. These types of substitutes are often chosen by people because of availability and cheapness.

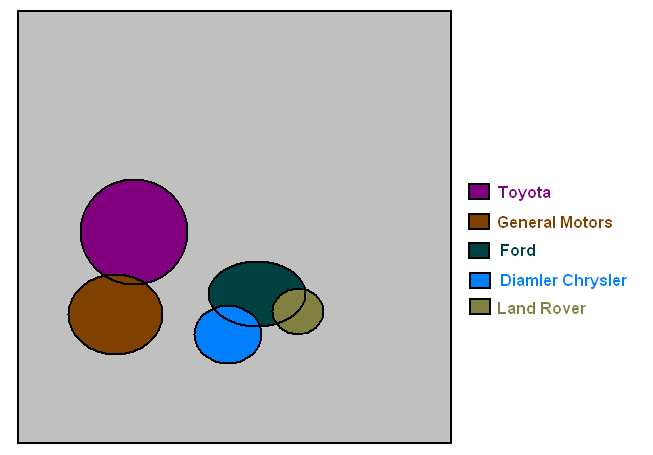

- Rivalry among existing firms: As noted earlier, the global automotive industry is fully saturated featured by a number of manufacturers along with their numerous offerings. Toyota has also to face many smaller and larger competitors at both domestic and global levels. The potential competitors of the company are General Motors, Honda, Ford, Mitsubishi, Land Rover, and BMW etc. So, Toyota selling of hybrid cars in compared with other market players can be shown as:

Along with that set of analysis, Toyota gets specific competition from both direct and indirect competitors. The former one involves General Motors, Nissan, and Honda while the later incorporates Tesla Motors, Phoenix Motorcars, Zap Cars, Mercedes Benz, and BMW. Along with other approaches, the company mainly focuses on two firms, especially for hybrid vehicles (Berthhiaume, Joshi, Longdo & Seshadri 2007). That are:

- General Motors

- Honda

Analysis of both company’s business models is essential which incorporates cost and value advantage of each one with an additional identification of individual strengths and weaknesses. Both of the companies similar business system flowchart, as:

Strategic overview through CSR policy

At present, both Toyota Industries Corporation along with its subsidiaries are taking part in positive sustainable development plan from especially community perspective. In this regard, the management has taken some strict ethical rules to obey domestic, national, and global laws for maintaining the selected codes of conduct within its business operation (Annual report, 2009). Therefore, Toyota’s CSR commitments regarding some groups are as below:

- Customers: Focusing on the basic philosophy of “Customer First”, the company has developed a number of creative, safe, and standard goods and services to the targeted customers for enhancing their standard of living (Johnson, Scholes & Whittington 2008). Moreover, the management team is strongly committed to serve ongoing information, which would help enough the customers in selecting and serving any Toyota car.

- Employees: Proper respect is given to each single employee with unbiased employment scopes, reasonable employment conditions, and favourable working surroundings. In association with all of those facilities, management also plans to implement proper human rights policies engaged in its value addition services, build an effective communication media and treatment according to cultural baseline and so one (Robbins & Judge 2007).

- Business co-operatives: The Company’s management is liable in giving proper honor to the vendors, intermediaries and other corporate co- operatives for the development of long- term intimacy with them with a greater influence of mutual growth and trust. It also exposes a non- prejudicial view in selection of such partner regardless their nationality or religion through an assurance of maintaining fair competition according a foreign nation’s trade laws of competition.

- Shareholders: The top management itself along with all the employees within Toyota is strongly motivated to enhance shareholder value for long- term. In this regard, the company arranges a proper exposition of operating and financial results (DeCenzo & Robbins 2005).

- Local communities: Toyota’s management is effectively keeping track in the root of sustainable growth of the company by reducing negative impact on natural environment through their business functions including a practice of performing tasks in order to lower the effect of Toyota brand on changing atmosphere and biodiversity. Similarly, it promotes different technological experiments for adopting environmental harmony with a core intension of cordial relationship with individual and corporate bodies for this purpose. It also takes adequate measures for respecting foreign culture, histories, and regulations. And finally, innovative mode for initializing clean, safer and better quality cars, protection of illegal monetary exchange in terms of any corporate partner, public agency or authority with integral honesty. From social point of view, management generally promotes and involves each organizational collaborator and recognizes them for their significance in natural environment and community development.

Managerial styles

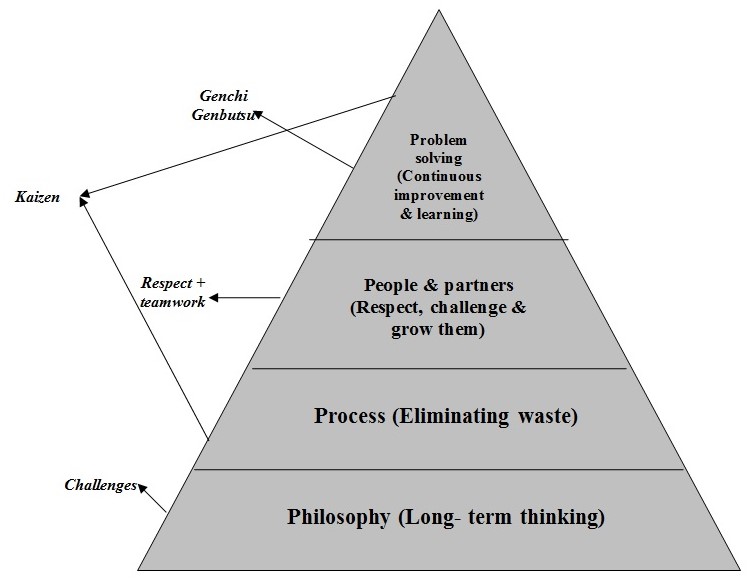

Like any other organizations, management takes a central role for the overall functionality and corporate affairs of Toyota. Before going through a critical analysis part, it is essential to understand the popular “4P” model through which the company operates its managerial tasks (Liker 2005, p. 3). Such as:

Such framework would take more explicit and interrelated form as below:

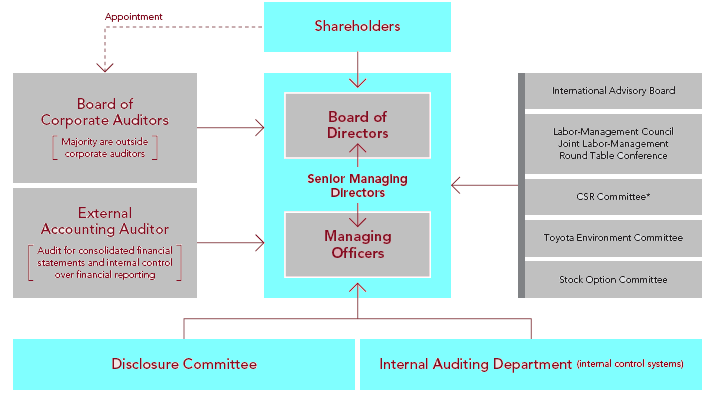

Thus, the formal management structure of the company can be shown as:

Implementation of TQM

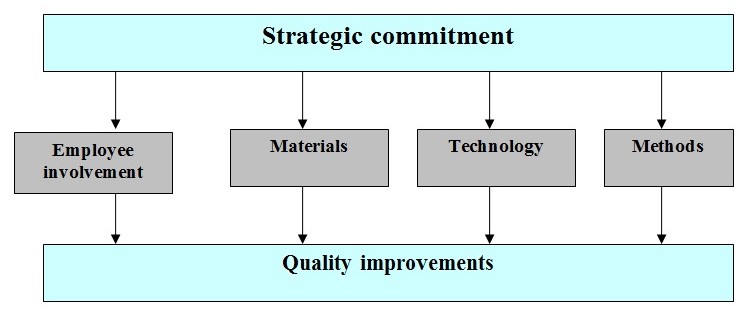

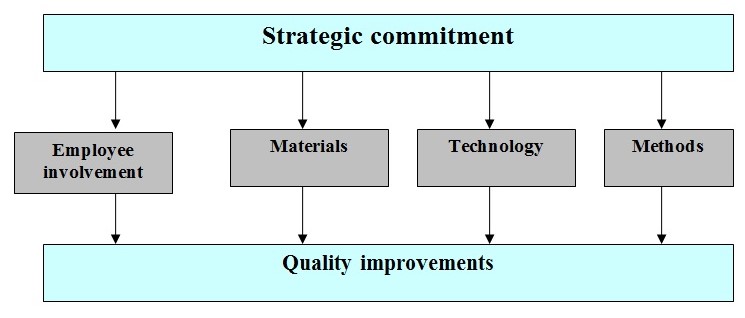

As mentioned earlier, Toyota’s managerial philosophy is can be characterised three major factors among which implementation of TQM (Total Quality Management) is significant one (TQM 2009). TQM can be defined as a strategic commitment by the top management for emphasising change within the overall approaches of the business for making quality is a guiding factor in each work it performs (Griffin, 2006). So, the entire process view of TQM can be shown as:

All of those ingredients will discuss below:

Employee involvement

Toyota is one of the most significant companies of the world, which offers a flexible environment containing a number of leverages. According to many industry experts, the basic reason of the company’s continuous innovation is the creativity and participative features of its huge employees. The company’s decision- making generally follows very front- line structure consisting of production, distribution and retailing. In this regard, the well- known JIT (Just- in- time) production formula makes it possible to enhance manufacturing efficiency in 58 nations of the world because of the involvement of lean personnel in decision- making relating car production and supply chain of the company (Chopra & Meindl 2008). The strategic management of Toyota influences the employees to perform the job in such way, which would be better than the previous one. Regular workforce introduction similar to this enhances the possibility in improvement of simultaneous innovation. Proper justification, incentives, and gratitude are integral part of this process. Additionally, the internal corporate culture is another factor, which affects each employee qualities, capabilities, and energies within a better orientation of broader mission, vision, and goal of the company for maximizing value of the shareholders. From this point of view, Toyota tries to identify the intended needs of each employee as well as what are the possible obstacles which would be faced in meeting those needs by searching of potential ways to come over those obstacles, which would also be realized in various individual unit of the company itself. Problem- solving schemes seems to mostly appropriate here for motivating these personnel better. For achieving the logical goal of a business regarding profit maximization, employees are taught to gain loyalty of the target customers while like many other top global firms, Toyota likes to apply such proceedings for developing employees through a dispersion of Toyota Way and Culture of Collaboration with an accomplishment of collaborative mechanisms. Similarly, they using interactive videos, teleconferencing through various task- specialized tools etc. Toyota has been formed an employee supportive environment (Peppers & Rogers 2006). So, the attitudes and behaviour of qualified personnel of Toyota can be evaluated under Covey’s 7 habits of highly effective people (Covey, 1999). The evaluative variables under Toyota consideration are explained as below:

- Be proactive – The special training and interactive working environment of the company motivates it internal personnel for taking responsibility of eager initiative to perform a task willingly.

- Have a clear vision – under this habit, employees are well- known about the core organizational philosophies along with target goal through which he/ she has to move strongly oriented by personal goal achievement.

- 1st things 1st– Under this motivation, employees emphasise more than operational significance rather than hurry;

- Think win-win – This thought teaches an employee about participative thinking while not all internal people will work in competitive mode rather than participating mode which is highly influential in gaining gradual improvement of each department.

- Listen than talk – Motivating by this vision, an employee likes to go through a process of deep understanding for enhancing work efficiency and specialization.

- Value difference – Toyota’s employees are globally highlighted for their innovative thinking and contribution on corporate success. Such personal quality can also be seen in developing product quality innovation in terms of adding value to it.

- Keep learning – Enlightened by this motto, the R and D team members of Toyota are simultaneously involved in new product, component or ideal generation purpose, keeping an internal drive developing individual knowledge of a fact.

Materials

Another important part of TQM is improving the quality of raw materials and components the Toyota uses. Normally, the company tries to accumulate different auto parts and components from renowned raw material suppliers of the world but in case of some contingencies, the company is bound to source those components from local vendors whatever the quality would be (Annual report, 2009).

Technology

Along with a steady practice over other technological developments, today the company is mostly reinforcing consumer’s mind with the development of hybrid vehicle labeled as “Hybrid Synergy Drive”. Through such kind of technological exposition, the company had been able to manufacture 1 million cars in 31st May, 2007 followed up by 2 million units in 31st August, 2009.

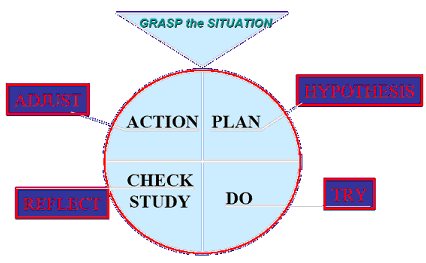

The Deming cycle

This is another managerial tool for ensuring continuous improvement program of a company that can be adopted in Toyota case in order to judge such effort by them (Walton & Deming, 1986). The four stages logical chart is presented below:

As shown in the diagram, the cycle starts from planning for accomplishing a specific task. In case of Toyota, top management as Board of Directors with a formal meeting generally forms such plan. Performance of a task may involve strategic, timing, technological or other sorts of error which need to be checked. After verification and exposition of erroneous issues, specific and objective oriented act is undertaken. This cycle is effective enough to improve intended quality force at each functional department of Toyota. Since it is an ongoing process, keeping a close truck with accomplishment of such cycle would be resulted in logical vision of a company in enhancing the quality of each produced vehicle. It also acts as effective mean leadership model practiced within the firm (Toyota Industries 2009).

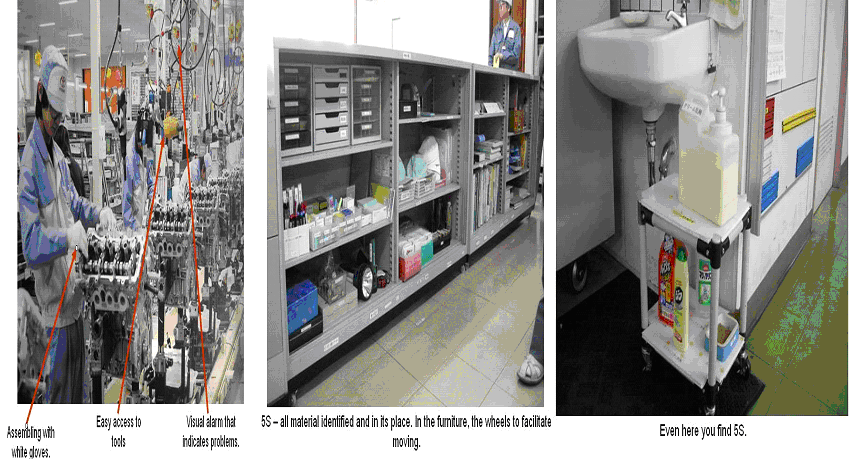

Implementation of 5s

This is another aspect of controlling quality, which is widely used by Toyota from macro to micro level (Toyota Motor Co. 2009). Such as:

The 7- S Framework

According to Pascale & Athos (1981), this framework is a competent managerial checklist for defining or analyzing a company. Adopting this structure in examining Toyota’s managerial strategies would reveal a series of variables as following:

- Toyota’s strategy

- Corporate structure

- Manufacturing and operating systems

- Shared values

- Organizational skills

- Employee orientation

- Identification of functional style

Thus, the analysis starts from identifying the core organizational strategy of the company for gathering a primary overview about it. Different studies suggest that Toyota generally sets ups its core business strategy by integrating various improvement variables of different fields of marketing, human resource, finance, production, technology and supply network etc. which suggest for moving towards a qualitative and development phase by maximizing both customer needs and shareholder’s value. Then, then company follows a simple organizational structure focusing mostly on shareholder’s empowerment and values followed by top to medium and finally, line management relationship. Organizational systems refer to the plans and policies adopted by the company in terms of production, operation and other related procedures necessary for assisting management unit. Through shared values, Toyota can combine all the hard and soft resources within it to achieve intended goals. Skills are both individual and corporation related while individual skill is reflected by the performance of employees working in different sections of Toyota ranging from production to sales. On the other hand, corporate skills are reflected by per department performance of management regarding R and D, HR, supply chain, finance, and marketing. Staffs are the people employed as permanent or temporary workforce of the company and finally, style is the overall domestic and international functional attitude through which the company performs its regular activities.

Kotter’s 8 phases of change model

Toyota is one the adoptive automaker in the world for a distinctive adoption and implementation of change strategy within many aspects of its production cycle (Kotter, 1990). So, several phases of organizational change regarding Toyota are discussed below:

- Install a sense of urgency: Exposition of change model can be started from the period of late 1970 while for the first time Muskie Act had been posed on international automobile industry. Although an imposition of such law had resisted by global car manufacturers with a further promising boundary of developing new technology, from that period, Toyota had adopted a change philosophy for individual development with a vision of exploring a cleaning and fuel- efficient vehicle, which would be considered as environmentally friendly car. However, in recent years, the philosophy and formation of overall managerial board has been changed motivated by some external forces as urgency. At the same time, the impact of globalization and harmonizing the competitive pressure of technological development are also acting as major catalysts for installing a sense of innovative change in corporate strategy (Annual report, 2009).

- Create a coalition: For technological support, Toyota had collaborated with 2i technology and the like as well as international expansion, it had to goes through several market entry strategies, like- to establish its presence in Chinese market, Toyota has be perform a joint venture agreement with a local counterpart (Psabilla 2007).

- Develop a clear vision: In this context, Toyota had developed distinct global market streaming up and sustainable development strategies as “Contribution towards Sustainable Development” for operating towards that goal (Toyota. 2009).

- Empower people to clear obstacles: Toyota has established the “Five Values” which have been accumulated as “action guide” which trains their workforce to imagine about themselves and specify about certain actions which need to implement for inflowing a change. After such determination, the employees then share the assumptions among them as well as share indifferent personal values that are going to be promoted by them for the forthcoming growth of the whole Toyota Industries. Additionally, Toyota had introduced effective empowerment policies for idealizing its huge workforce about potential hurdles for organizational achievement of those specific objectives. For this, sophisticated training and development programs along with financial and fringe motivational schemes are given to them (Peppers & Rogers 2006).

- Secure short- term gains: All of the projected game plans need to be secured first while that kind of requirement would be tough to maintain sometimes because of some internal and external policies and contingencies. Internal factors include focusing on long- term profit maximization and growth, economies of scale etc. while external factors are long- run adoption of national and international regulations, inflationary events, differentiated marketing techniques etc (Toyota Industries 2009).

- Consolidate and move forward: This stage basically focuses on nature of environmental adoptability of the company while it needs to have a mutual contact with each group both inside and outside of the organization. Such groups incorporate employees, partners, customers, government, each management, investors, suppliers, and other remaining stakeholder bodies. Establishment of a co- operative relationship with each such group has leveraged the company in many aspects its functionality. For example, after facing a managerial calamity in 1950, pollution crisis in 1970 and trade related vulnerable exporting difficulty in 1980, by using the concept of working consolidation, Toyota had been able to pass all of those through broader thoughts and creativity. In this case, the company also focuses upon healthy and safe organizational surroundings with a better motto for a better learning by employees, technological growth and participative learning for enhancing the strength of the company. Besides, in 2003 Toyota gained a huge production capacity of up to 500000 motor cars but unsuccessful to satisfy public demand fully. Thus, an emergency sense of their employees had motivated to work jointly for meeting customer needs and strengthening the fundamental base of the company to overcome that challenge (Toyota Motor Co. 2009). Such as:

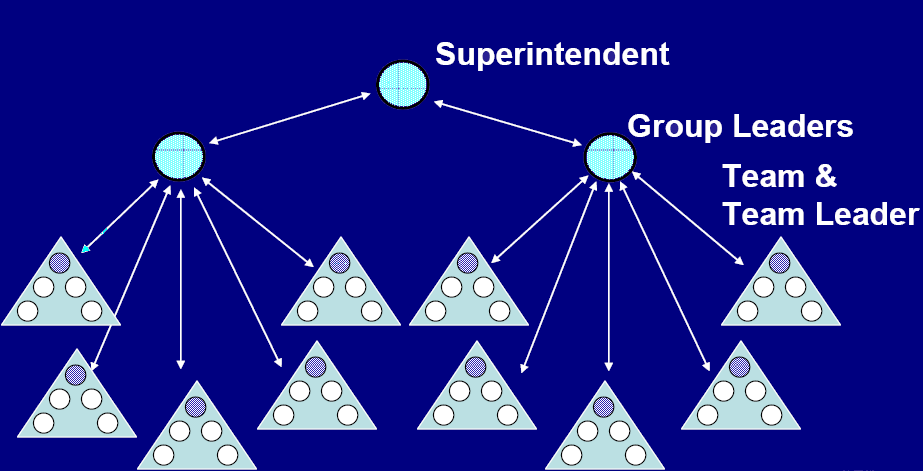

- Anchor changes: Leadership contributes for all sorts of success and non- success situation of a business since it is a core function of management. In this regard, like many other functional alteration of business, Toyota had introduced a lean leadership concept within its basic business strategy, which usually focuses on participative management. From 2003, the company reformed it management board, which evolves relatively few number of directors than before. According to this reformation, Chief Officers are Directors who are posing highest authorities of individual operational unit. Here, non- board Managing Officers apply original activities. Through such process, Toyota now can successfully implement its changed environmental concern because of the top management’s linkage with on- site operations rather than exact managerial tasks. Therefore, change in anchor has been resulted into corporate fruitfulness of making direct decisions on the basis of actual conditions emphasising real judgment of employees on strategic management with easy and quick implementation potential (Sten & Elsemarie 2005).

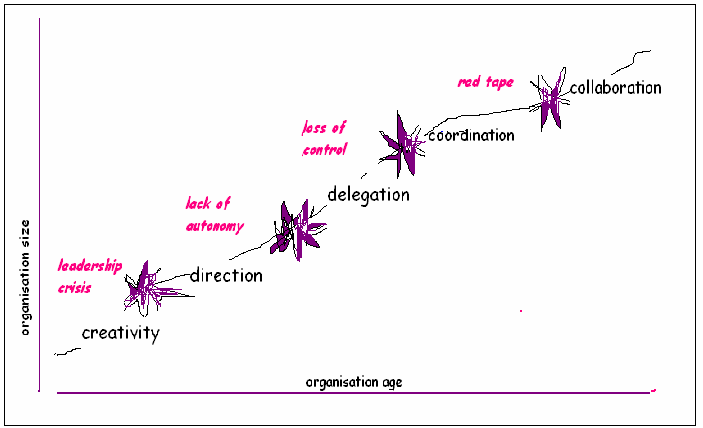

Greiner’s 5 stage growth model

According to Greiner, 1998, a company’s growth can be measured as an ongoing process of some combination of development phases. From this focus, Toyota’s technological and global market extension growth can be evaluated as below:

- Step- 1: At the first stage of growth model, the company must show creative appeal as a symbol of innovation. Toyota’s R and D department devotes is engaged in such type of innovation through which the company had been able to manufacture many differentiated items including fuel free, hybrid and electronic motor cars and thus symbolizing special creativity of the company (Psabilla 2007).

- Step- 2: At the next phase of growth, organizational management of this company is posed to maintain the responsibility to set a framework about how the projected tasks will be accomplished through the development of a business plan. Under this consideration, the Directors of Toyota had been emphasising over operational plants to have a practical review in generating growth (Toyota Motor (2009).

- Step-3: In this stage, the company needs to understand various forces essential for ensuring sales growth. For example, at the middle of 1980, the President of Toyota had obtained a specific understanding of American culture with the vision of realizing a greater success potential from that part of the world. After some years, Toyota had also developed a joint ownership agreement with American company General Motors as NUMMI, which assured corporate growth factor in such a period while the whole industry had been negatively suffering from excessive protectionism. Such type of fruitful delegation had been resulted in 50000 units, huge production sites, manufacturing of 200000 automobiles and creation of merely 3000 employment opportunities within 1988 (Toyota Motor Co. (2009).

- Step-4: Co- ordination is one of the most significant phases that should be accomplished carefully. Mangers need to set a mutual co- ordination with each operating unit, which is an integral part of macro- level development. Continuing the example placed at previous section, Toyota’s president had managed his company in such way so that it would maintain a high level of global co- operation in both general management and technical fields (Sten & Elsemarie 2005).

- Step-5: The final phase of growth model is collaboration, which refers to accomplishment of every task with team effort. According to the historical review of Toyota, Toyota’s R and D section is the best example of that pattern of group work. Additionally, the ongoing human resource of the company is motivated by performing operations in-group while the corporate leadership vision and other related functional sections of the company also follow a collaborative model for gaining long- run efficiency with gradual development (Annual report, 2009).

Therefore, certain issues can be suggested for continuing the growth stream with new and forthcoming offers of the company (Berthiaume, Joshi, Longdo & Seshadri 2007). Such as:

- Maintenance of desirable quality;

- Adoption of local cultural context, which would be accepted and appreciated by potential customers.

- Adoption of various marketing strategies for increasing market awareness;

- Government incentives and supports for having a quick foreign country growth.

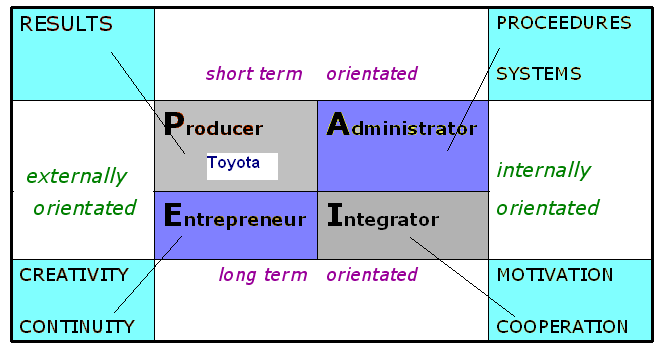

Adizes’s PAEI management roles

According to this model, the role of Toyota’s management will be possible to examine under consideration of corporate partners regarding manufacturer, entrepreneur, administrator, and integrator (Adizes 1979). Therefore, the actual situation can be viewed as:

This diagram is clearly indicating the role dispersion of each business partner in terms of functionality and value maximization. Here, producer is Toyota itself as a car manufacturer, which is basically concerned with external outcomes and emphasises on short- terms goals. The administrator is internal force of Toyota which is also short- term oriented body focusing in different patterns of organizational processes and systems needed to accomplish specific managerial tasks. Entrepreneur or the founding body of the company can characterise by creative thinking and drive to continue the business operation at any cost. It is such force of management, which plays a differentiated role in existence, profitability, and long- run sustainability of business. This force is also oriented by external environment in terms of handling responsibility and performance of all other corporate affairs. In addition, the final force is integrator, which can be featured by establishment of employee motivation in such way, which would be effective in generating legal co- operation among them to achieve long- run goals of the company through an internal process (Toyota Motor 2009).

Leadership and motivation

According to Newstrom & Davis (2006) leadership is the process of affecting and assisting others to work enthusiastically toward achieving objectives. More specifically, it is such catalyst of a firm, which transforms potential into reality. So, the functionality and success of leadership process is dependent and integrated with some other bodies within an organization like the following way:

In Toyota, leaders are obliged to perform several tasks (Womack & Shook, 2009). Such as:

- Getting each personnel motivated for an adoption of scheme to solve difficulties along with improving their individual task.

- They are giving guarantee that individual’s task is formatted for delivering value to both customers and company.

So, the leader’s role in the production system of the company can be shown as:

Toyota’s leaders are well committed for the performance development of employees working under them (Newstrom and Davis, 2006). Such as:

At present, oriented by the modern philosophy of lean management as well as lean leadership, the company’s top management has decided to follow that approach in terms of active observation of manufacturing sites through an active participation of sub-ordinates in making decisions (Toyota Motor Co. 2009). This functionality would take a shape as:

Therefore, the chronological development of Toyota’s leadership style can be divided upon three phases while the 1st phase is an old “Director” style focusing on performing the tasks on autonomic way. From 1980, “Empowerment” style had evolved emphasising on opportunity of performing the tasks on employees’ way. Lastly, Toyota had adopted the present lean style focusing on the slogan of “Follow me and let’s figure this out together”. Thus, it can be said that Toyota’s leaders desire to observe assessable outcomes while they are known about a process view of financial outcomes. Similarly, they can also feel that such results amplify past presentation of that proceeding with a precaution of managing them from today (Womack and Shook, 2009).

Resolving the issue of 5 who’s to 5 why’s: Modern corporate leaders do not reach to an instant conclusion rather than forming the condition by asking the reason while such initiative emphasise to view the right problem without finger- pointing searching of at which criteria that blame would be placed. By maintaining a responsibility of attaching the actual employee-bearing task, Toyota leaders can actually empowering their people (Womack & Shook 2009).

Resolving the issue of problem- hiding to problem- solving: Since almost all the functions are planning and problem oriented, it incorporates a basic motto to lead people as “No problem is problem” through a quick evolvement of problem and managing them promptly because hiding of them would be depressive for the process (Womack & Shook 2009).

Technique of control with flexibility: The rules of Toyota way offer a differentiated orientation, direction, and “control” with eligible flexibility in order to resolve dilemma observed in preliminary periods (Womack & Shook 2009).

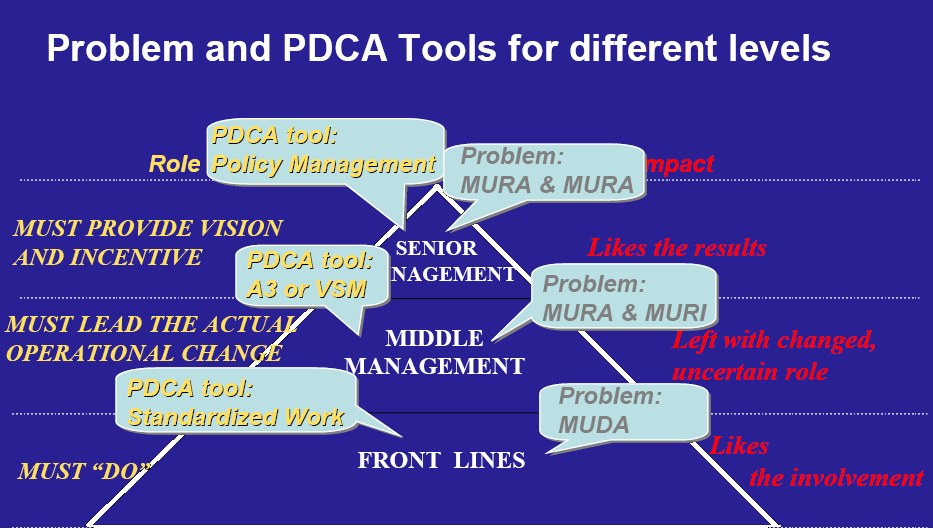

Thus, the practice phases of lean leadership can be visualized as:

However, several potential problems can be notified by implementing P-C-D-A tools like:

As a result, the basic three keys of lean supervising can be summed up as:

- Top management’s time expansion and integration with line management;

- Implementation of “why” process continuously.

- Respecting corporate workforce.

These combined processed will be resulted into:

Finally, the company uses TQM method to improve quality of global leadership through a partial approach of JIT technique. In this regard, the “”Science SQC” had become famous for emphasising on team effort which had organized a training program for all Toyota leaders as “SQC leaders” or “SQC specialists” while another step had also been initiated to train the management team in 1994 remembered as an illustration of a joint group of Toyota and a foreign organization (Amasaka 2009). Such as:

Such process had internationally dispersed regarding Europe, Canada, North America, and other developing regions as a symbol of effectiveness. Since those approaches are helpful in increasing the efficiency of administrative partners in resolving a complicated issue with optimistic corporative outcomes, all of those activities and gaining are related with team’s group work regarding general staffs, line management, administrative bodies and indirect functional sections along with affiliated and non- affiliated vendors at the planning and application phases (Amasaka 2009, p.10).

The company leaders were also been conscious about learning and mistakes process through which they have identified some difficulties in early TPS. Because of that mistake, the newer vision of continuous improvement program has learned by leaders with a sophisticated potent of success (Womack & Shook, 2009).

On the other hand, the HRM strategy in Japan is widely followed by six pillars of national employment practice as:

- Lifetime employment

- Company welfare

- Enterprise unions

- Seniority- based reward system

- Quality consciousness

- Consensus management (Gomez- Mejia & Balkin 2004)

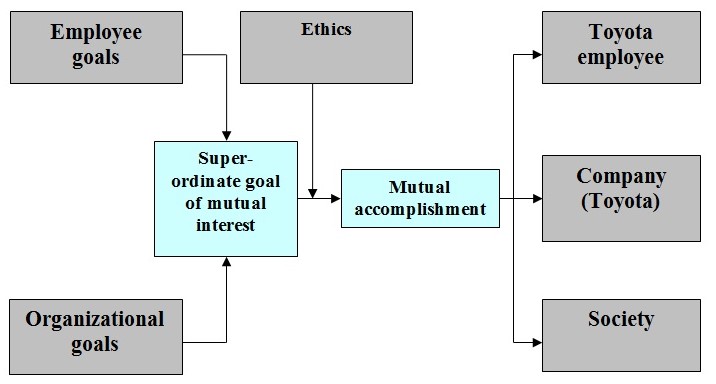

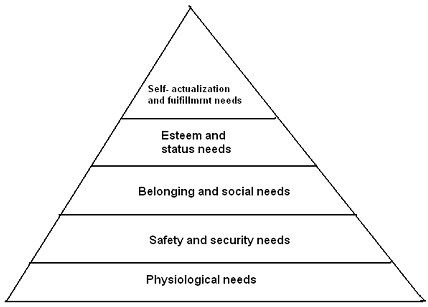

Enlightened by all such provisions, Toyota is one of the world market leaders in terms of generating employment opportunities for above quarter million people within its various operational sections (Hisrich & Peters 2006). From the beginning of 1992, the company had employed about 5500 employees while after passing a longer period that number had increased at a gigantic level. However, Toyota’s HR department is committed to motivate employees with physical, financial, and psychological ways (Annual report, 2009). Moreover, it offers a mutual interest in motivating people through a close integration with organization and society to achieve a shared goal, as:

Therefore, it can be concluded that the company’s HRD motivates people by following Maslow’s hierarchy of needs (Newstrom & Davis, 2006). It is placed below:

According to this model, Toyota’s personnel are being motivated from physiological factors followed by safety and security issues, which are generally satisfied by salary and different compensation packages, fair, secured and safe working environment considered as lower- order needs. Then the rest 3 higher- order needs are satisfied through adequate respect, similar job scopes, non- discriminatory employee treatment, group participation and teamwork, participation in decision- making and the like (Toyota Motor Co 2009).

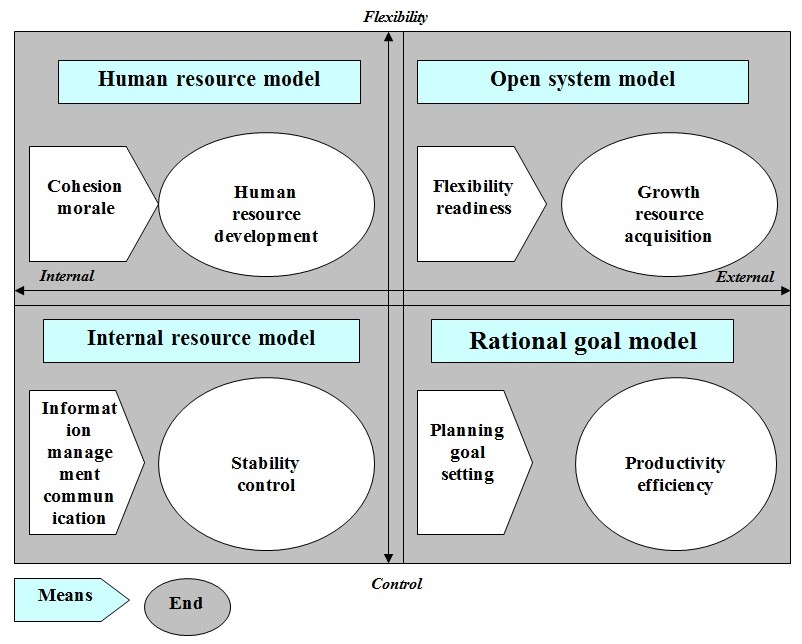

However, all of such patterns of managerial and leadership strategies tend to serve competing values to enhance overall performance of the company (Quinn & Rohrbaugh 1983). This can be viewed as:

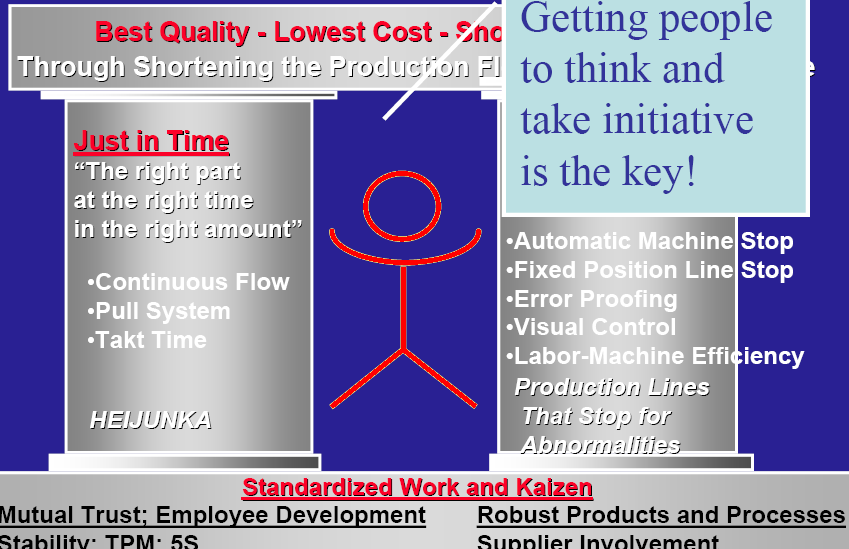

Manufacturing strategy

From the overall discussion above, it can be realized now Toyota is leading today’s automotive market in terms of a number of strategic superiority and tactics from which production is one of most significant ones (news.cnet.com).

As an aftermath, the company has substituted General Motor regarding huge production and sales while from 2005, one of its subsidiaries named as Daihatsu Motor Company had manufactured about 8.54 million cars proved as efficient production feature to capture the emerging Southeast Asian markets. Other than, it has production sites in majority areas of the world, especially for the production and assembling of automobiles in domestic markets (Toyota Motor 2009). Basic manufacturing guidelines are:

- Focus on long- run rather than short- run goals.

- Establishment on ongoing system flow for highlighting the problems.

- Using of “pull” strategy for eliminating overproduction.

- Level away the work pressure.

- Development of an environment of terminating to permanent problems for ensuring quality;

- Ensuring of standardized activities, which are the baseline of continuous development and power of workforce;

- Utilization of visual control to reveal difficulties;

- Using of sophisticated technology and realization of actual situation via genchi genbutsu.

- Production of each unit with a proper reflection of improvement.

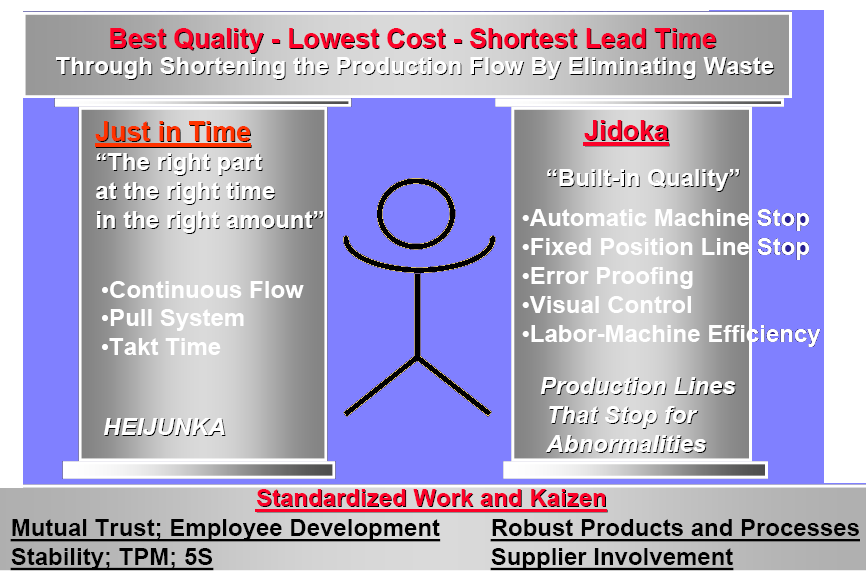

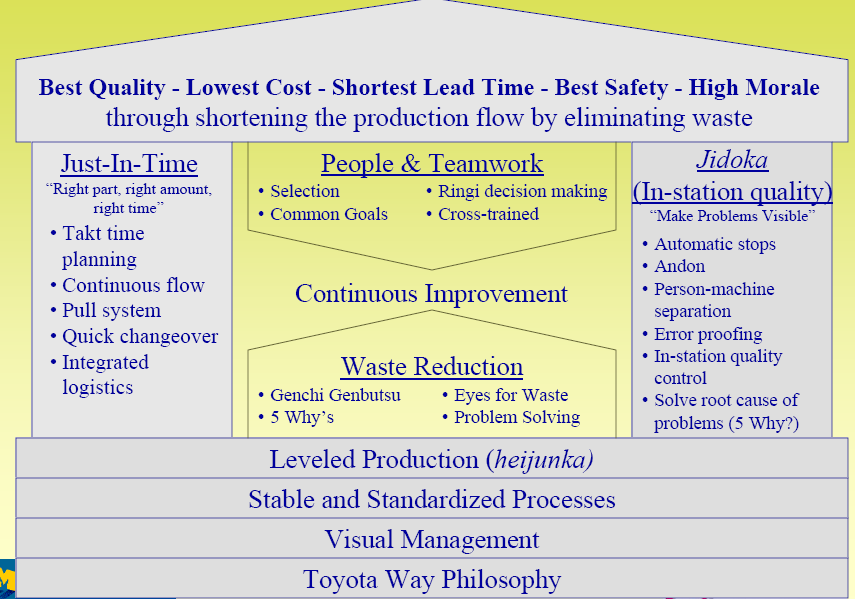

At a glance, Toyota’s production system can be presented as:

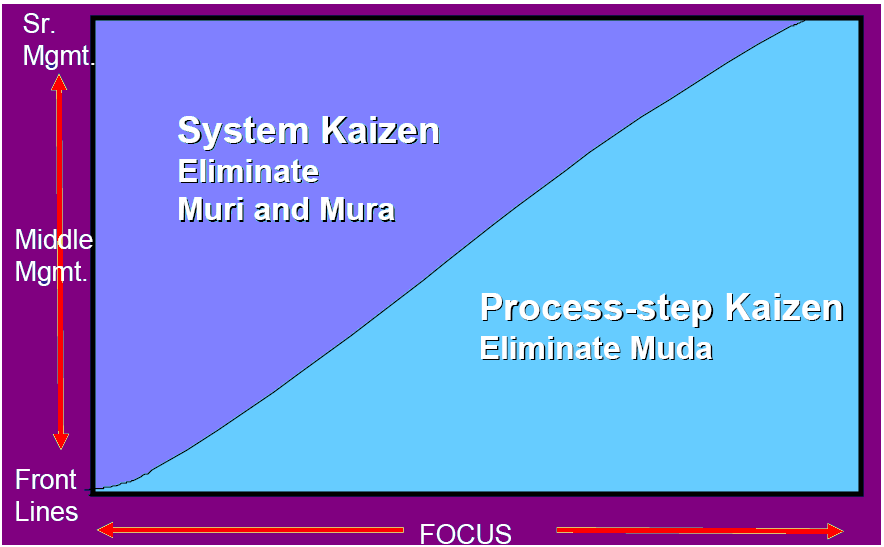

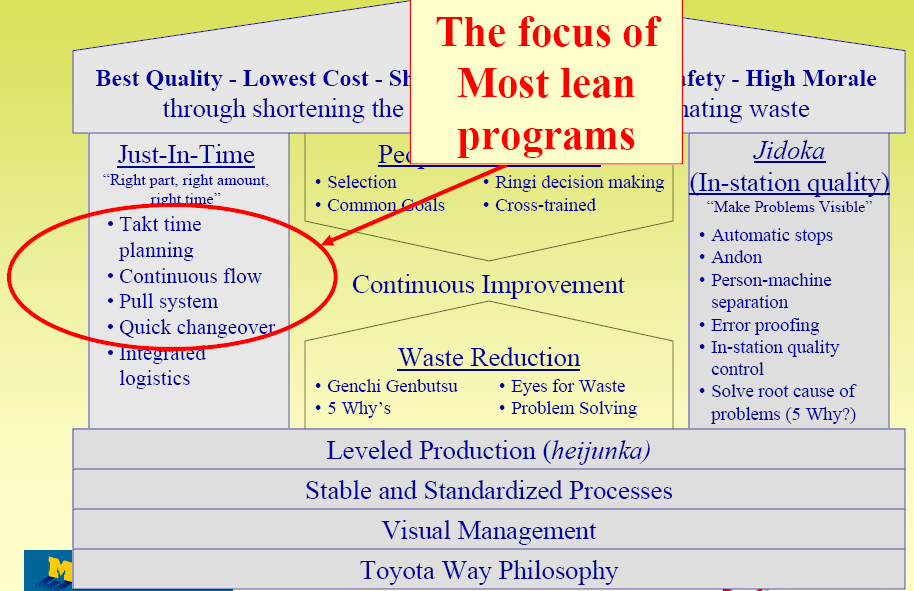

Upon this system view, the major attention has given on JIT or Just- in- Time as:

JIT is a new pattern of managerial technology that delivers a high level of QCD goods better than other market partners via the process of “Market Creating” tasks concentrating mostly on consumer needs (Amasaka 2009, p. 4). Our projected car-manufacturing firm generally uses this strategy in three corporate units as below:

Additionally, the JIT adoption for global partnering model can be show below:

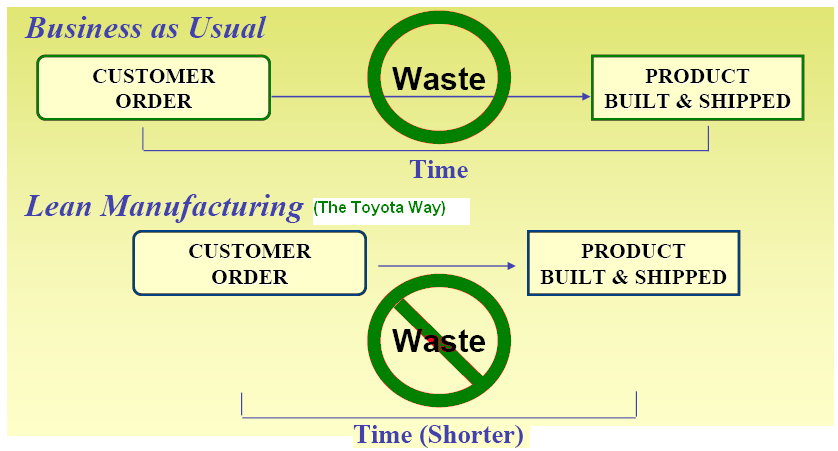

Such JIT strategy intends Toyota to move through a sequential way of applying lean strategy in worldwide production. Lean production philosophy means, a manufacturing strategy than lessens the timer between consumer order accommodated with product development or shipment through a removal of origin or waste (Liker, 2005). While Toyota implements this strategy in the production of diversified modeled cars, it would like the following:

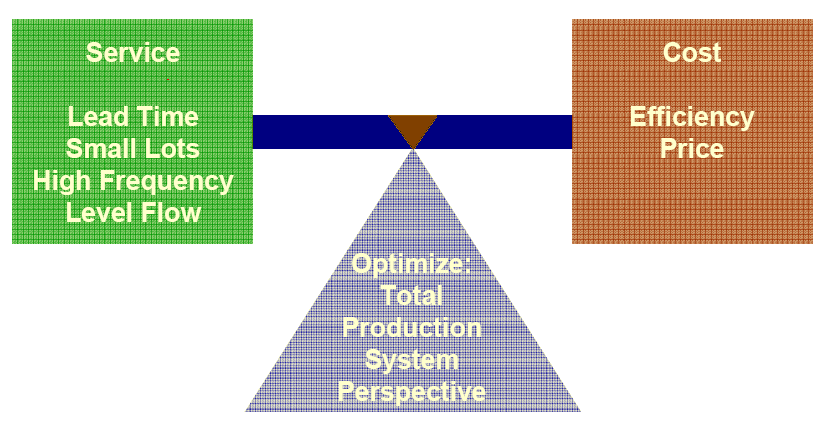

Supply chain strategy

Toyota has become successful regarding quality, cost, and better maintenance of lead- time rather than other car industry competitors. Such performance has dispersed through the core theme of Toyota Production System along with Toyota Way. From that point of view, Toyota tends to bear three performance goals within its logistics and supply chain network (Liker, 2005). That are:

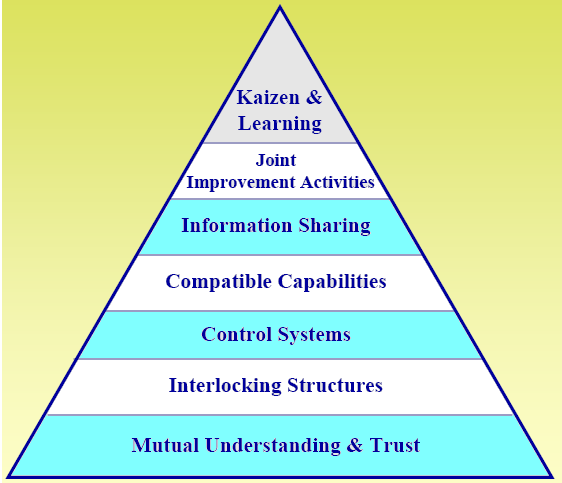

Therefore, there are 7 ingredients in supplier co- operational hierarch which are as below:

The features of all such stages are explained below:

- Mutual understanding and trust: This stage incorporates loyalty, commitment of co- operation, mutual respect regarding each other’s qualification, emphasise over Genchi Genbutsu and the like.

- Interlocking structures: It involves alliance framework, interdependent systems, and corresponding sourcing.

- Control system: In terms of controlling logistical flows, Toyota focuses on measurement techniques, response, and selected pricing.

- Compatible capabilities: Here, the company implements engineering and technological sophistication, operational efficiency, and problem resolution technique.

- Information sharing: This is crucial stage of Toyota’s supply network that is extensively characterised by proper accumulation of data and analysis, using of virtual language and effective as well as timely communication.

- Joint improvement activities: It evolves VA/ VE, improvement of intended vendors and introduction of group discussion.

- Kaizen and learning: Such stage assists the company in broader thinking with extra criteria of identifying mistakes so that adequate steps can be taken to correct them for ensuring further success.

At the same time, the company poses a glorious history to build and improve the performance and relationship with its global supply networking. The case of North America is one of the most significant in this regard while Toyota has made a close focus on TPS skill building of 55 vendors in 1997 with team support and further assistance through 5 experts in buying task to PDA. Some other grouping for such development planning incorporates Blue Grass Manufacturing Association (BAMA), Quality Assurance Division with TPS knowledge, Toyota Supplier Support Center, Toyota Motor Sales etc. (Liker, 2005).

Suppliers are considered as addition parts of the company regarded as above than “buying parts” which should be treated similar to the normal associates. It is possible to establish long- term relationship with them through a tier structure that emphasises on responsibility levels. Additionally, it is required to maintain stronger cost destination and timing. JIT and product development system are some integrated processes, which are also implemented. Several variables are mostly practiced in the supply network of Toyota as outsourcing, partnership, production planning technique and finally, the association of supplier. For example, in China, Toyota has to combine itself with local vendors for enhancing intellectual growth of factory divisions as well as becoming successful in “international manufacturing” for China fuelled promotional leverages by improving domestic production (Annual report, 2009). In case of Japan, the company has to notice the traditional theme of “Japan Supply System” like below:

Keeping this theme in mind, Toyota would adopt Strategic Task Team model to show the development and integration process of local and international suppliers in a complete supply web:

For a proper implementation of this model, the company will use some managerial tools involving product, engineering, quality, QCD, value task group, and HR strategy. Recently, in Denmark, the company has introduced a huge implementation of lean approach while it has reflected by adoption of such approach by above 80% Danish production houses (Amasaka 2009, p.7).

Technological strategy

By keeping an upgraded flow of technological development, Toyota has been focusing on the generation of plug- in hybrids termed as “Toyota Plug- in HV” and other sorts of electronic vehicles. This category is known as “e- com”. Beyond U.S.A, Toyota manufactures Hilux in customary and double cab, diesel, and gasoline engine with the modern versions of 2WD and 4WD. According to the two episodes Top Gear TV show by BBC, the Hilux car is practically indestructible. In producing various kinds of motorsports, the TTE (Toyota Team Europe) had introduced Formula one for CART along with Le Mans Series. This formula had also used for construction and supply of engine. TRD (Toyota Racing Development) is another output of technological advancement since the company is also putting its knowledge and expertise in non- automotive functionality in terms of production of Aerospace, Philanthropy, robotics, higher education, and finance (TQM 2009).

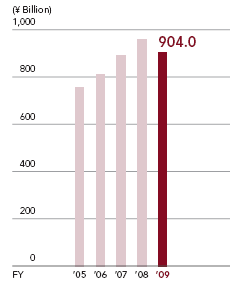

At the same time, the company is most promising for the orientation of e- commerce technology by a declaration of establishing partnership of its sales department with i2 technologies in terms for becoming an online service provider for motor vehicle replacement components industry (Farmer, 2003). This new segment is called iStarXchange, which are planning to operate singularly with a vision of involving many car equipment producers, vendors, individual installers, and wholesalers. The sophisticated R and D team is leaded by Masatami Takimoto who is the executive vice president of Toyota is now passing its effort for the introduction of so many commercial technologies regarding standard diesel engines, commuter electronic vehicle powered by a small battery, approximately half- dozen patterns of hybrid cars and cells of fuel (Annual report, 2009). The R and D expenditure of the company can be visualized as:

Thus, the R and D maintains several principles for offering delivered level of quality through technological support in relation with delivering safe and clean automobiles by enhancing the projected standard of living at each operating area as well as technological sophistication of the firm (Annual report, 2009).

Financial strategy

Toyota is motivated by financial growth in terms of 3 core strategies regarding growth, efficiency and stability since management thinks that keeping a deep balance among these three variables ranging from medium to long- run would be resulted in continuous and sustainable development through an additional enhancement of organizational value (Toyota Motor Co. 2009). Thus, combination of those three factors is presented as:

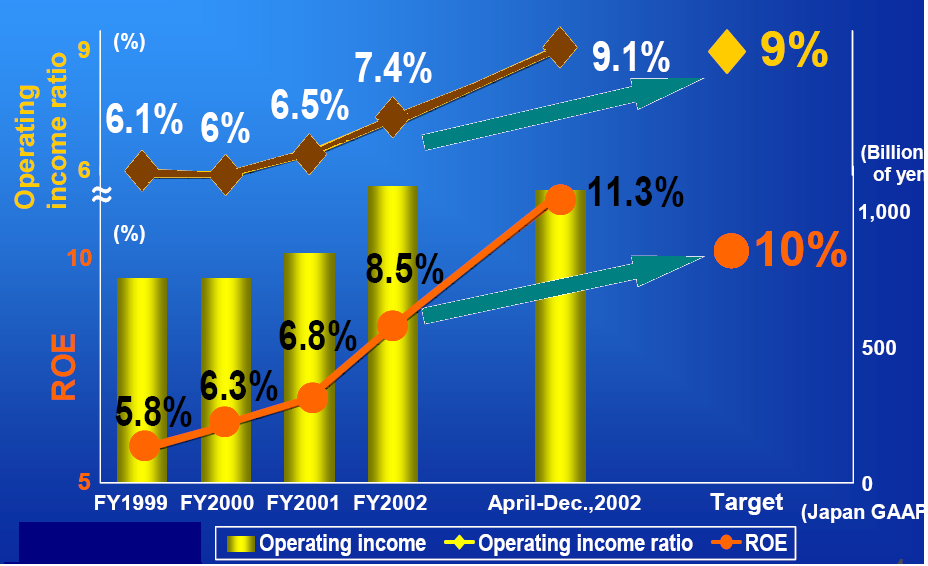

A company’s growth can be measured by technological development, potential market expansion, and satisfactory supply factors for the formation of newer market segments, increasing supply for satisfying international demands, and modifying marketing efforts for reflecting higher level of financial efficiency in terms of active investment and capital funding. During the fiscal year 2008, through the advantage of forward- forecasting capitalization, the company has been able to generate a positive cash flow with huge capital expenses of merely ¥1480.2 billion along with R and D expenses of ¥958.8 billion. During the same year, the company generated a marginal operating earning of 8.6% with a ROE of 14.5%. It has also achieved a higher profitability in new offer initiation with the support of key international model and future promotion of creative functions, developed manufacturing systems for achieving a lean supply capacity to the highly demanded zones. At the same time, Toyota is also trying to gain company shares for continuing and improving prosperity and capital competence. Through stability, Toyota aims to keep a slid monetary base in terms of adequate liquidity and steady stockholder’s equity. At the end of 2008, company owned current assets of about ¥4200 billion and stockholder’s equity of ¥11800 billion. Thus, the company needs to maintain sound monetary conditions regarding capital spending for having long- run sustainability (Toyota Motor Co. 2006).

Therefore, it can be realized that Toyota’s entire financial scenario is greatly impacted by some internal and external ingredients (Toyota Motor Corporation, 2003). Such as:

- Alteration in economic conditions influencing, competitive atmosphere, and Japanese, North American, European, Asian, and some other operating markets of Toyota;

- Variation in exchange rate, especially in terms of yen, dollar, pound, and euro;

- Corporate potential in understanding manufacturing efficiencies and capital investment through accurate time management;

- Possible changes in local and global rules, obligations and litigations that would affect production, sales, emissions, fuel economy of motor cars along with any future projection of regarding those facts.

- Public argument cost regarding warranty and many other sorts of customer satisfaction tools.

- Lack of political stability and corporate qualification in adopting newer technologies or development plans to enhance profitability.

- Vulnerable pricing condition of oil and other raw materials for negatively affecting profitability.

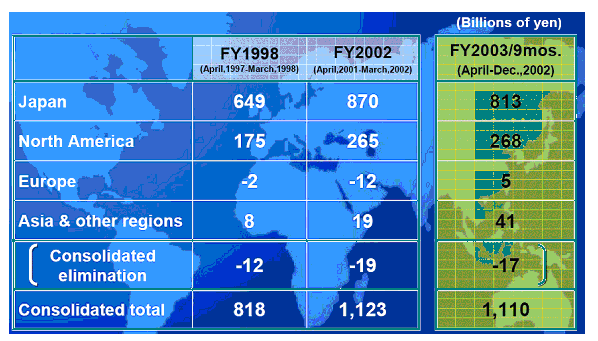

Analyzing the global car market scenario, it can be observed that total production has been sharply increased within last 13 years with approximately total output of 6.31 million in 2002 (Annual report, 2009). Thus, the projected change in international economic circumstances can be shown as:

The business performance of the company regarding market segment and other elated financial projections are presented below:

Among many types of business operations, automobile operation is most significant for the company from overall context because of its major share of 880% total incomes previous to deduct sub- segment revenues in 2009. The company’s major industry share in terms of selling vehicles for the same period can be denoted like- 26% in Japan, 29% in North America, 12% in Asia and 14% in Europe. As we know, the international car market is intensely competitive which is continuously influencing by many factors among which recession is one of the most difficult to handle. For this financial calamity, Toyota has lost about half of the total market share particularly in Japan, U.S.A, and Europe causing a slowdown financial growth for business (Toyota Motor Co. 2009). Thus, the consolidated automotive sales picture of the last three years can be shown as:

The graph is showing that in Japan, there is constant declining figure of sales growth indicating Toyota’s loosing of local market share more than other foreign ones. Although foreign selling of cars has been improved in 2008, this trend has fallen certainly in the next year. In 2008, North America, Asia, Europe have experienced upward sales along with more manufacturing locations, initiating newer modeled cars has been more effective in meeting customer’s demand (Annual report, 2009). In 2009, sales per unit declined, specifically, North American and European zone containing larger profit share as:

Among various types of risk factors, fluctuation in currency rate is most vulnerable for the company since it poses two major patterns of risks to it involving translation and transaction risk. Through the former risk, Toyota’s current state of financial result would be changed by other operating regional exchange value in relation with Japanese yen. The later is another type through which the liabilities and expenses of the company would be deviated from currency framework regarding sales and assets. It is a primary pattern of risk mostly affecting the Japanese manufacturing market. In 2009, it has also experienced a lower revenue achievement by ¥5612.6 billion, 23.2% less than 2008 of ¥18564.7 billion. Such pessimistic outcome has generated for lower sales volume throughout the year with alteration in sales mix accounted as ¥3400 billion, currency fluctuation translation rate by ¥1833.8 billion, and the lower selling of automobile parts. Through an elimination of fluctuation rate, the company would earn a net income of ¥20398.5 billion as a 15.6% negative figure than 2008. Similarly, the lower sales and operational income figure in other parts of the world are equally been affected by Japanese factor. Operating expenditures have lowered by 12.6% to ¥20990.5 billion in 2009 for ¥2100 billion production expenses, ¥2060.1 billion translation rates and ¥54.8 billion lower costs of R and D (Annual report, 2009). Such costs have been lowered for high price of steel, expensive metals, aluminum, plastic and other sorts of raw materials while some other issues are:

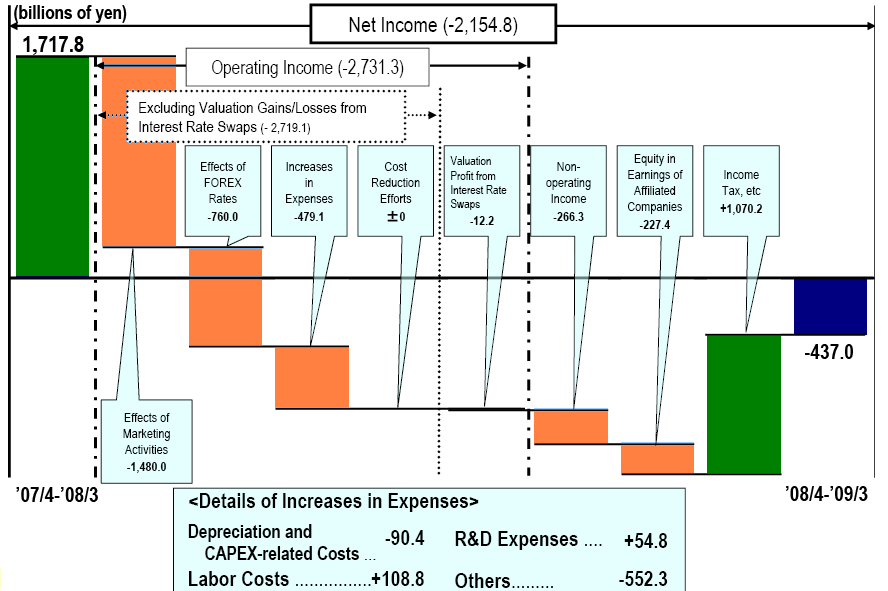

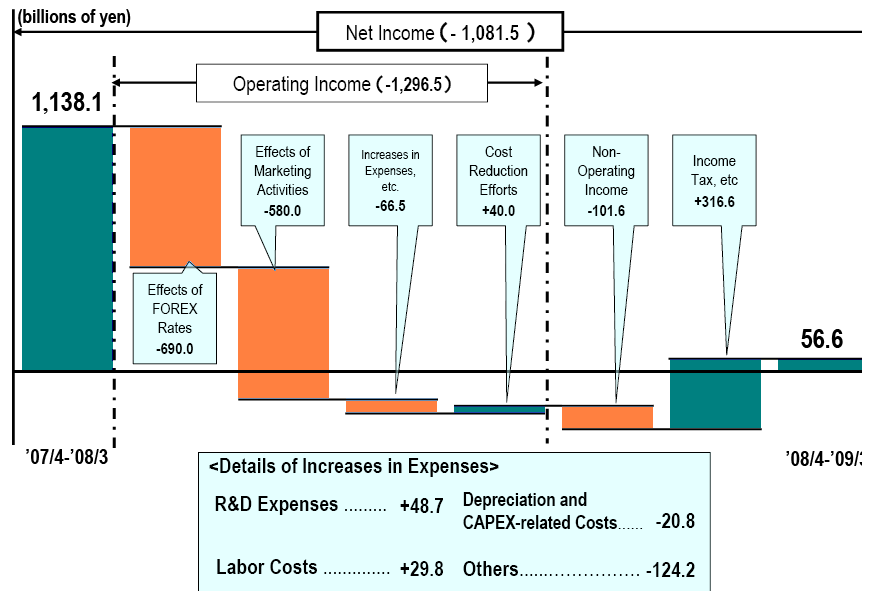

The company’s net profit reduced by ¥2154.8 billion with a loss of ¥437.0 billion than 2008, as:

The above financial outcome can be analyzed deeply, which will show the following scenario:

Based on all of that information, a future assumption regarding the company’s 2010 financial situation can be projected like:

Marketing strategy

From the beginning of its operational period, Toyota has been continuously concentrating upon its effectiveness in car marketing. Such effort is gradually been developed day- by- day to keep a close touch with in serving modern consumer demand as a basic corporate marketing theme spreading out from local to national and finally, to international level. However, the company is also committed with a stronger promise to deliver high quality vehicles to its target customers. Since it is greatly motivated by positive ownership practices, it has been introducing their brand with a number of slogan during different phases of time, such as, “Oh, what a feeling!” in 1978, “I love what you do for me, Toyota!” in 1980 and 1990 and “Get the feeling” in 2001 etc. (Toyota Motor Co. 2009). Thus, the entire marketing focus of the company can be discussed under some empirical marketing theories, such as:

Market structure analysis

Under this conception, Toyota tends to measure the number of total automotive sales in each market segment for throwing a single market strategy and for marketing of an individual product; it just considers the global sales of that motor car followed by potential position of other branded cars (Capon & Berthiaume, 2007). Such as:

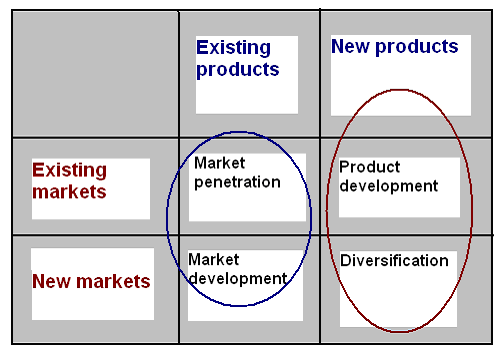

Ansoff’s product/ market expansion grid

This is strategic growth theory through starting up or acquiring business outside Toyota’s current motor vehicles and markets. This grid is helpful in making an overview for the identification of growth of cars by market penetration, market development, product development, or diversification (Kotler & Armstrong, 2006). Thus, the Ansoff model casing Toyota is presented below:

- Market penetration: Here, Toyota sells existing modeled cars to its existing domestic and global markets. It means that the company raises revenue in terms of promoting their automobiles, re- positioning the corporate naming, and the like. Here, the basic theme is Toyota does not make a change in their present models without any intension of seeking new customers.

- Market development: According to the annual report 2009 of the company, Toyota markets their current offerings in a new market. For example, the act of it in entering into Chinese and Indian market for selling the same branded cars fall into this criteria. Through this strategy, it creates a new market development for the same brand.

- Product development: At this point, Toyota develops and innovate new offerings to replace the ongoing ones. For example, through an innovation of safety vehicles with a slogan of “moving, turning and stopping” in terms of generating effective systems involving VSC, ABS and Brake Assist, the company is trying updating or replacing their current versions of automobiles as well as marketing them to accessible customers.

- Diversification: Here, the company produces completely new forms of automobiles to new audiences. In this regard, Toyota makes both related and unrelated diversification. The former one occurs when Toyota explores its newer segmented production of hybrid vehicles or mini family car for especially Chinese market and the later occurs when it invests in some other industry not related with automobile including robotics and finance.

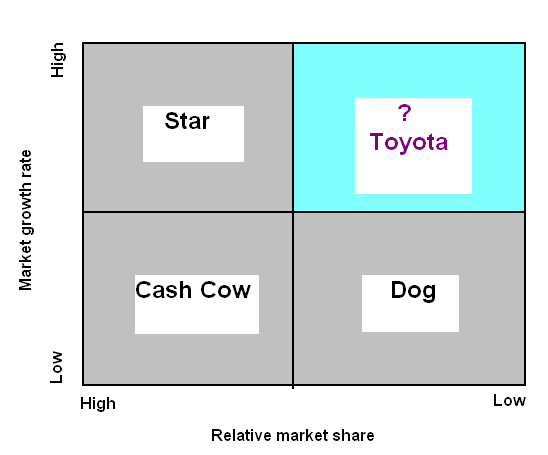

The Boston Consulting Group approach

The BCG model is a portfolio planning process to evaluate Toyota in terms of relative market growth rate as well as relative market share. It has four ingredients among Toyota occupies a distinct position regarding those noted conditions (Kotler & Keller 2006). Such as:

- Star: It is the high- growth, high- share business, or product with heavy investment and rapid growth. Before the recessionary period, Toyota’s position can be placed at this point rather than recent one. However, it is very difficult for any other automobile manufacturer for becoming in this position in this economic distortion.

- Cash cow: This is the low- growth, high- share business, or product.

- Dog: It is the low- growth, low- share business, and product.

- Question mark: This is the low- share business unit in a high- growth market. Toyota occupies this segment of the matrix because of its recent fall of huge market share in Europe, North America, and Japan but with a favorable growth rate accompanied by rising consumer demand.

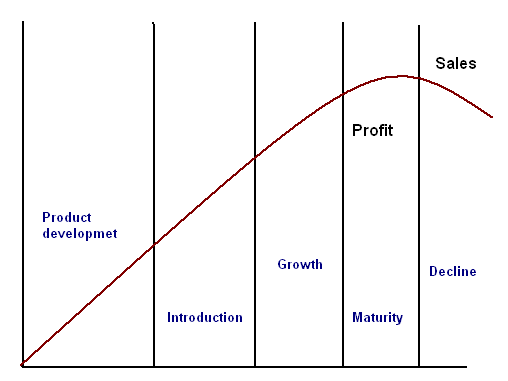

Product life cycle (PLC) analysis

It refers to the course of a product sales and profits over its lifetime, which incorporates five separate stages regarding product development, introduction, growth, maturity, and decline (Thompson, et al 2007). Such as:

So, the automobile lifecycle condition of Toyota can be shown as:

For example, if we consider Toyota’s hybrid model car as a sample for analyzing this PLC concept, then the following scenario would be come out:

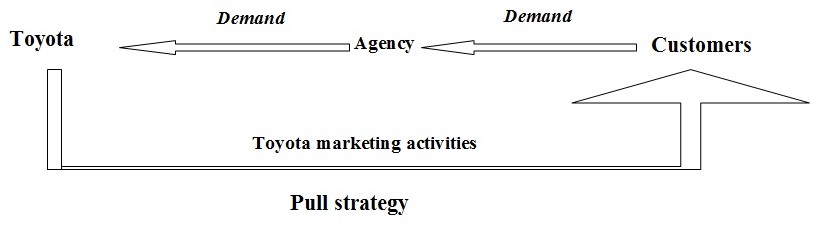

Push/ pull strategy

Push strategy means “pushing” the product through distribution channels to final consumers where the manufacturer directs all the marketing activities toward channel members for the reminding them in order to carry out the product and to promote them to final customers. On the other hand, with a pull strategy, the producer directs marketing activities towards final customers for inducing them in buying a product. If pull strategy is effective, customers will then demand the product from channel members who will in turn demand it from manufacturers. Here, customer demand “pulls” the product through the channels. Toyota actually follows this strategy by directly convincing their target customers to buy their existing and new automobiles. Customers then also show adequate attention and interest to buy Toyota cars (Stoner, Freeman, & Gilbert 2006). It can be presented as:

Segmenting strategy

It means dividing the market into smaller groups of buyers in terms of distinct needs, characteristics, and behavior requiring the separate offers or marketing mixes. Among a number of segmenting strategies, Toyota generally follows geographic, demographic, and behavioral segmentation. According to the 1st one, it separates its entire market on geography base like- Japanese, North American, European, and African etc. market. The second one involves segmenting the market in terms of age, family size, family life cycle, income, occupation, generation, nationality etc. variables. The final technique involves segmenting on the basis of benefits sought, user status, and usage rate and loyalty status.

Targeting strategy

It reveals the Toyota’s market segment opportunities, which primarily incorporate segment evaluation in relation with segment size and growth, structural attractiveness and corporate objectives and assets. According to the annual report 2009 of the company, next, the company selects target market segments consisting of a set of buyers sharing common needs or characteristics that it desires to serve. There are also alternative strategies relating this issue, such as, undifferentiated, differentiated, and concentrated and micromarketing strategy. Among those, Toyota has adopted differentiated or segmented marketing strategy because deciding to target several market segments and designs separate offers for each. For example, Toyota has manufactured hybrid Plug- in car for the customers who want to use a vehicle that would be environmentally friendly through contributing a sustainable environment.

Positioning strategy

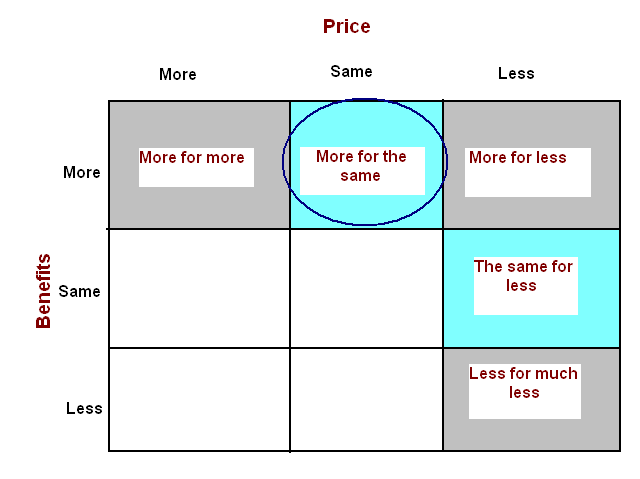

A product’s position is the way through which it can be defined by the consumers on important attributes. It means that, through a positioning strategy Toyota would be defined by the customers as an automobile regarding its important features involving quality, speed, price, and durability etc. (David 2008). Some essential stages of Toyota’s overall positioning strategy are:

- Positioning map: With a perpetual brand positioning map, Toyota would be able to understand the perception of target customers towards their brand in terms of other competitors, such as:

- Choosing a positioning strategy: It involves identifying possible competitive advantages, choosing them perfectly and selection an overall positioning strategy. For the accomplishment of 1st stage, Toyota tends to emphasise more on product and service differentiation by delivering globally standard automobiles at relatively reasonable prices. The company also concentrates on image and channel differentiation globally. At the 2nd phase, Toyota decides on the number of differentiating factors to promote that generally incorporates various features like- important, distinctive, superior, communicable, preemptive, affordable and profitable. After, in selecting an overall positioning strategy, the company first identifies value proposition, which refers to the full positioning of its brand or the complete mix of advantages upon which it is positioned. Such as:

As the circle indicates, Toyota goes through with “more for the same” value proposition in order to make a stronger fight with other market competitors in terms of offering high quality motor vehicles at lower price.

- Developing a positioning statement: It refers to a statement that summarizes the company or brand positioning while Toyota has been developing a number of adoptive and effective positioning statements in different periods of time, for example, development of brand positioning statement as “Moving forward” in 2004

- Communicating and delivering the chosen position: At the final phase of positioning strategy, Toyota takes several steps for delivering and communicating its desired position to target automobile customers. In a need of delivering a position, development of a competitive marketing mix structure is necessary.

Purchase decision map

It is decision-making process of an individual customer or an organization in buying a motor car according to personal need which must be identified by Toyota (Capon & Berthiaume, 2007). It is a five-stage process that involves the following phases:

- Recognition: It is influenced by many factors regarding changes in life style, high price of gas, environmental thinking etc. while a customer would like to wait for an environmentally friendly car regarding PHEV.

- Information: Customers generally tend to find out information about the desired model from internal and external source. Such as, many people seek information via internet.

- Evaluation: Here, customers assess alternatives in terms of model specifications, affordability, accessibility, and emotional variables. For example, PHEV buyers mostly concentrate on technical, monetary, and functional features of a car.

- Choice: People make choice regarding the outcome of functional, financial, and emotional reactions of buying decision.

- Post-purchase: This result of this phase would take two distinct shapes either in satisfaction or dissatisfaction. If the customer satisfied, then he/ she will make good comments about the car to the family and friends. Similarly, dissatisfaction will motivated a customer to react in negative way.

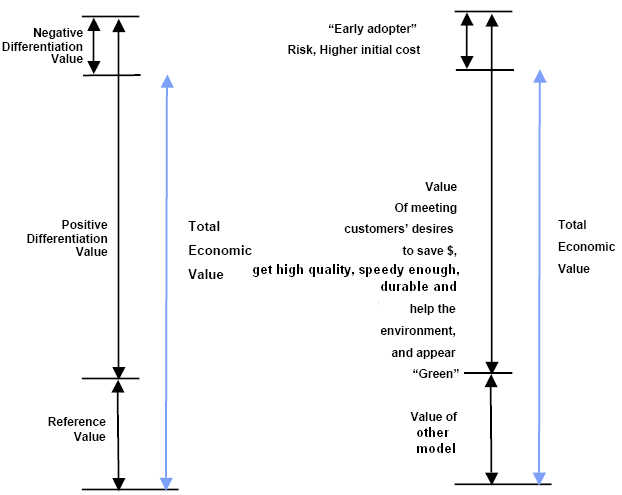

Economic Value for the Customer model

The EVC model examines the economic value that a customer calculates while purchasing a Toyota. This value analysis follows a measurement scale from negative differentiation to positive differentiation value and reference value (Capon & Berthiaume, 2007). It can be shown as:

Branding and logo

Deep attention on logo had posed from 1936 when the company changed its first passenger car Model AA from “Toyoda” to “Toyota” which had been highly effective since the word implied a sense of good luck and prosperity to Japanese. The recently used logo of Toyota had been first launched in 1989 which exposes a single “T” for the company name while the background is related with international technological dispersion and unrestrained future potential.

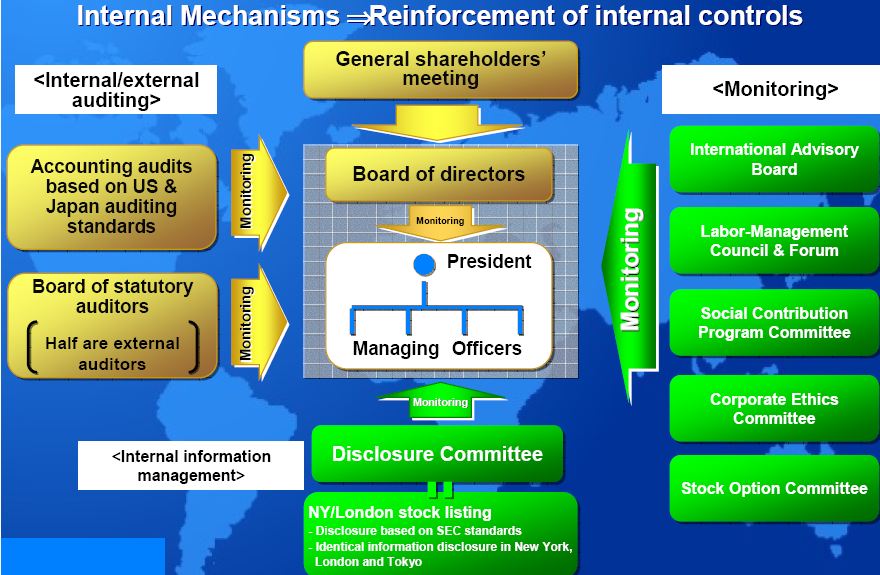

Strategic control

According to the guiding principles and codes of conduct, management of Toyota is basically oriented by problem identification as “Mondai Hakken” and continuous improvement as “Kaizen” processes (Toyota Motor Co. 2009). Thus, the internal controlling strategy of Toyota can be elaborated as:

- Directors are controlled by specific rules and regulations focuses by ethical codes and other relevant documents containing different organizational obligations.

- Any sorts of operational decisions are taken only after passing of Board meeting and like this with different cross- sectional leading personnel governed by adequate rules.

- Such discussions are also relevant in terms of reviewing and treating risks regarding corporate functions.

- Ensuring proper flow of information about Director oriented responsibilities through an additional checking of each single unit performance.

- Proper treatment of capital and funds will be accomplished by regular budgeting and other controlling techniques, arrange business activities and budget management rolling on the tasks by following “Ringi” process, which is a fruitful harmony- generating and supportive system. Again, necessary issues are submitted to the grouped meetings in accordance with their standard predictions in relating rules.

- Transparency of monetary information is maintained through keeping of such record in proper way by Disclosure Committee.

- For managing different risks, supportive managerial rules incorporate developing laws for preparing and issuing manuals based on its emergency in each unit.

- In terms of facing of any uncertain events including natural disaster, the company tends to ready manuals, perform urgency drills, and conduct diversification of risks and essential insurance plan.

- Management of stable techniques through per unit policy isolation from mid to long- run management plans along with singular corporate policies. Thus, the CEO and connecting officer generally leads and verifies Managing Officers stating on that policies through a delegation in order to adopt lean and time effective decision- making.

- There is an arrangement to gain a feedback from its stakeholders regarding outsider specialist those are actively amplified in entire managerial and operative actions.

- For assisting the employees with a track of corporate responsibility according to such legislations, Toyota is liable to teach so for ensuring continuous improvement program.

- For assessing risks, management morally conducts self- checks among each unit with CSR Committee report.

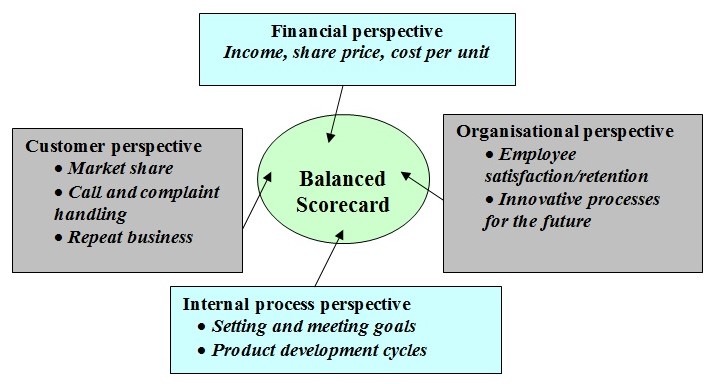

Balanced scorecard

At the ending part of the study, the balanced scorecard can be used to evaluate the overall managerial, networking, financial and marketing performance of Toyota. This scorecard has four performance measurement headings under which each relevant section of the company is possible to appraise (Kaplan & Norton 1993). Such as: